The challenge with OCA tape applications is to avoid the forming of air bubbles between material and tape during and after the application process. In the entire application set-up, air bubbles have a negative impact on the function of touch sensors and printed electronics.

Our optically clear adhesive tape solutions enable secure lamination and mounting in a wide field of printed electronics applications, and also in touch sensors in human machine interface (HMI) applications. They are particularly suitable for bonding applications on moisture-outgassing plastics such as PMMA or PC. In addition to their permanently high transparency, the adhesive tapes are acid-free and enable a bubble-free appearance at temperatures of up to 105 °C. They are also excellent for encapsulating the print edges of the most common screen printing inks.

The most important application fields:

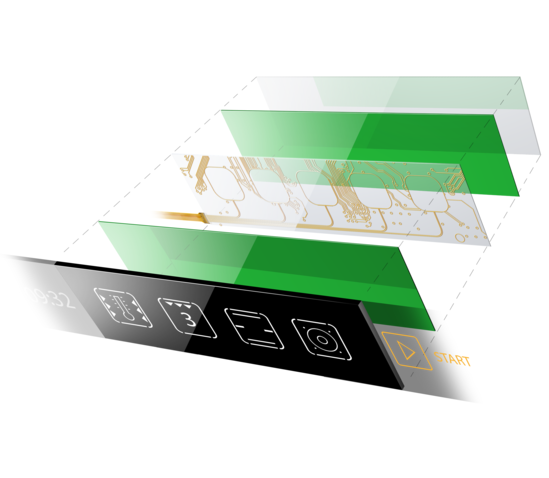

Lamination of printed electronics and assembly on plastic components

Bonding of printed overlay films on HMI devices

Our OCA solutions enable bubble free bonding after a temperature exposition of up to 105 °C:

1) Substrate

2) Lamination

3) Conditioning

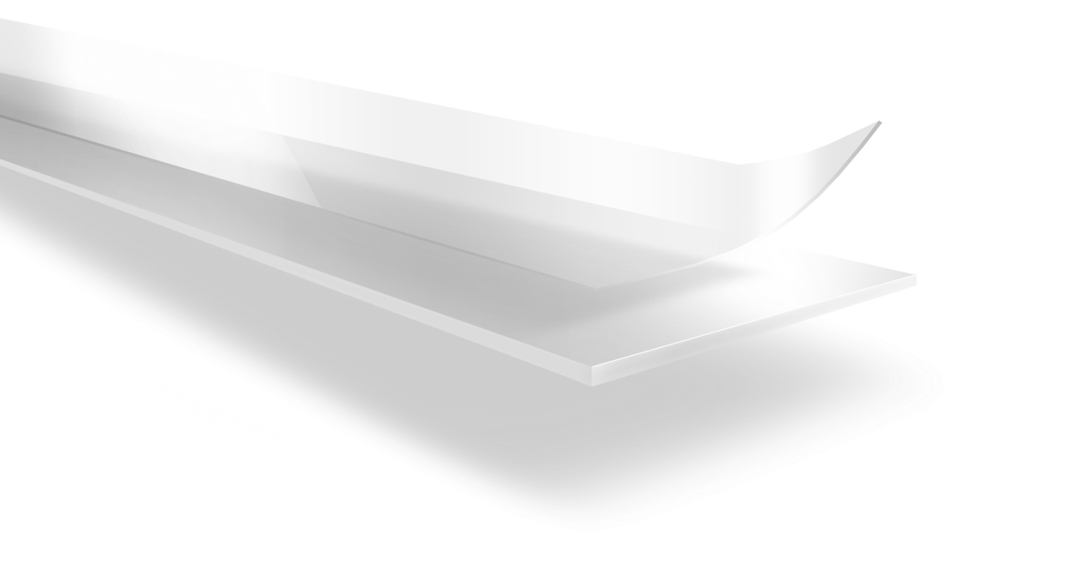

Clearly recognizable in direct comparison - Lohmann's OCA solutions are ahead of conventional OCA adhesive tapes on the market.

Other optically clear adhesive tapes (as an example the upper sample in the illustration) cast clearly visible bubbles after exposure to temperature. These affect the optical brilliance and function of HMI interfaces. For example, the sensitivity of touch sensors is reduced, or the backlighting of buttons and the visual appearance of displays are less visible. In addition, the effect of temperature can reduce the transparency of the optically clear adhesive tape - in some cases, this can even lead to haze or yellowness of the product.

Lohmann's OCA tape (the lower sample in the illustration), on the other hand, remains bubble-free after exposure to temperature. There is no haze or yellowness of the product.

Conventional OCA tape (upper sample) vs. Lohmann OCA tape (lower sample)

after temperature exposure - direct comparison

Your advantages

Our OCA tapes are available in two thicknesses. They are equipped with a transparent polyester film liner and a highly transparent pure acrylic adhesive:

| Product name | Construction | Liner | Adhesive | Thickness without liner [mm] |

| DuploCOLL® 26050 OC | Double-sided transfer tape | Polyester film, transparent | Pure acrylic, highly transparent | 0,05 |

| DuploCOLL® 26150 OC | 0,15 |

General technical properties

| Property* | Method | Substrate | DuploCOLL® 26050 OC | DuploCOLL® 26150 OC |

| Thickness [mm] | internal | Without | 0,05 | 0,15 |

| Peel adhesion 180° [N/25 mm] |

Internal 24h after bonding |

Steel | 20 | 25 |

| Glass | 20 | 25 | ||

| PMMA | 17 | 19 | ||

| PC | 17 | 19 | ||

| Stat. shear adhesion 4 h [N/625 mm²] |

Steel | 100 | 200 | |

| T-Peel 100 mm/min [N/25 mm] |

acc. to DIN EN ISO 11339 | PET | 16 | 23 |

| Acid value [mg/gKOH] | internal | Without | < 1 | < 1 |

| Temperature resistance | 500 h, 105 °C | Glass | Transparency 99 % Haze 0,6 % Yellowness 0,6 |

Transparency 99 % Haze 0,6 % Yellowness 0,6 |

| UV resistance | 500 h, 0,35 W/m 340 nm 63 °C | Transparency 99 % Haze < 0,2 % Yellowness 0,4 |

Transparency 99 % Haze < 0,2 % Yellowness 0,4 |

Optical properties

| Property* | Method | DuploCOLL® 26050 OC | DuploCOLL® 26150 OC |

| Thickness [mm] | internal | 0,05 | 0,15 |

| Transmission rate [%] (350-1000 nm) |

ASTM D1003 | > 98 | > 98 |

| Haze [%] | < 1,0 | < 1,0 | |

| Yellowness | ASTM E313 | < 0,2 | < 0,2 |

| Color L* | ASTM E308, D65/10° | 100 | 100 |

| Color a* | 0,0 | 0,0 | |

| Color b* | 0,1 | 0,1 | |

| Air bubbles | internal | 0,2-0,5 mm max. 10/m² | ≤ 0,15 mm max 100/m² |

| Particles | ≤ 6,30 mm max 100/m² |

*Data are average measurement data and not valid for specification.

Downloads

**Disclaimer:

The physical properties described in this data sheet are typical measured values or average measured values. All application-related assessments, information and recommendations are based on our best knowledge and practical experience. Many factors beyond our control are solely within the control of the purchaser and may influence the use and effects of our adhesive tapes in the specific application. Unless explicitly agreed in writing, we accept no liability for the suitability or usability of our tapes for specific purposes and applications, which are inherent in the specific use of the tapes by the purchaser. Unless otherwise stipulated by law, our liability for direct or indirect, material or immaterial damage to the purchaser resulting from the use of our adhesive tapes is excluded. The responsibility for the suitability for the purpose intended by the purchaser lies solely with the purchaser.