Debonding on Demand

Lohmann's Debonding on Demand Technologies integrate durable bonding solutions with the potential of smarter rework, easier repair, and real circularity in production. Engineered to hold. Designed to be released.

Designed for Disassembly: Smart Adhesive Solutions

for Reuse, Repair & Recycling

The future of product design lies in circular thinking – and that means making disassembly part of the plan. With Debonding on Demand, we offer high-performance adhesive solutions that hold strong during use, but allow for clean, controlled removal when needed. Whether your goal is reuse, repair or recycling, our smart bonding systems support sustainable decisions across the entire product lifecycle.

Driven by regulatory requirements such as the EU Green Deal, WEEE or the upcoming Battery Pass, industries are rethinking how products are assembled – and disassembled. Our debonding technologies help you meet these evolving standards efficiently, reduce material waste and enable smarter, more responsible manufacturing.

Residue-Free Removal

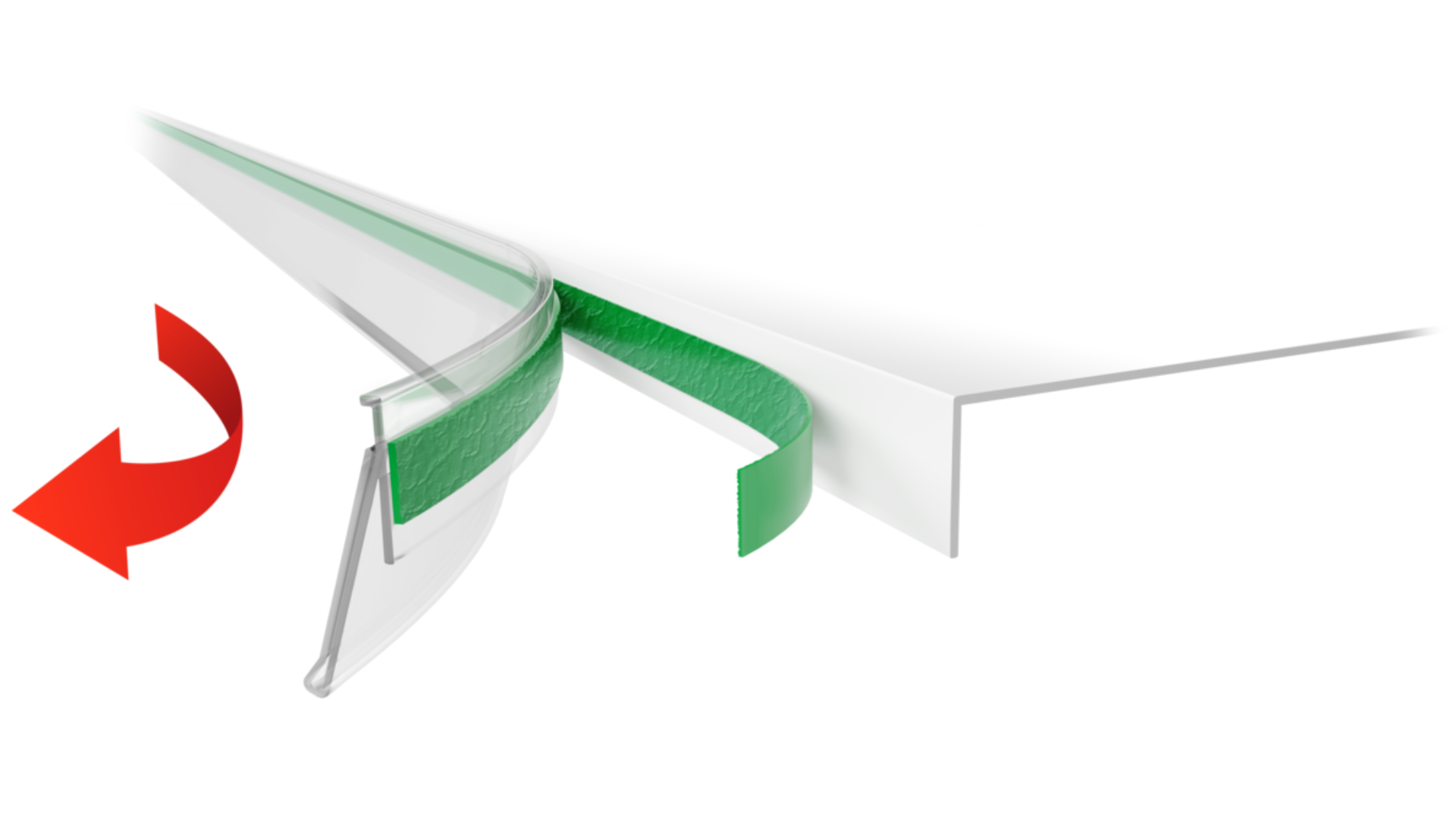

Conventional adhesives often leave behind unwanted residue, making cleaning difficult. Our innovative foam adhesive tapes with integrated reinforcing films allow easy, residue-free removal – for example, in supermarket scanner rails.

Repair & Maintenance

Making products repair-friendly is essential to a circular economy. Lohmann’s Hook&Loop double-sided adhesive tapes enable easy, tool-free maintenance – perfect for dishwasher panels, electronic components, and more.

Recycle & Reuse

Regulatory demands for recyclability are increasing, particularly for electronics like smartphones. Our smart debonding solutions, using UV light or temperature, allow components to be separated gently, preserving their integrity for reuse or recycling. This reduces e-waste, lowers environmental impact, and cuts costs.

Responsible Solutions in Every Bond

Integrity and responsibility as a foundation for customers, employees, society and the environment - this is our conviction and the standard by which we measure ourselves. Our focus: Creating sustainable products and business models and leading by example. We firmly believe that economic success and environmental and social responsibility go hand in hand.

Debonding at the Touch of a Button

Tailored for Your Needs

Debonding on Demand is an umbrella term for smart release mechanisms that allow adhesive bonds to be selectively and cleanly removed. Based on the DIN/TS 54405 standard, we offer solutions that match your technical requirements and product environment. With over 700 bonding system variants and 10,000+ applications worldwide, we develop tailor-made solutions that fit your exact requirements.

At the heart of each solution is the trigger – the way the bond is released:

Tearing

Temperature

Solvent

Electricity

Cutting

Combination

Stretching

Radiation

General Triggers: These rely on the natural properties of the adhesive system, such as responsiveness to heat or mechanical force. They are easy to implement and ideal when access is simple and safety constraints are minimal. However, their use may be limited in sensitive environments or where precise control is required.

Advanced Triggers: Engineered specifically for controlled and application-driven debonding, these triggers are integrated into both the tape design and product concept. Whether via UV activation, thermal input, or built-in mechanical release features – advanced triggers ensure safe, scalable, and targeted debonding even in complex use cases.

Lohmann: Your Development Partner Beyond Bonding

From automotive and electronics to medical and industrial applications, we create custom debonding solutions that align with your sustainability goals.

Ready to rethink adhesives?

Contact Peter Harendt (Head of Application Technology) to discuss your specific application needs.

Ready for what's next?

Discover how we develop advanced adhesive technologies, align functional performance with sustainability, and deliver reliable solutions for the challenges of tomorrow.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs