R&D for

Smart Bonding

From concept to conversion – with our adhesive expertise, we accelerate your innovations and create sustainable connections for the future.

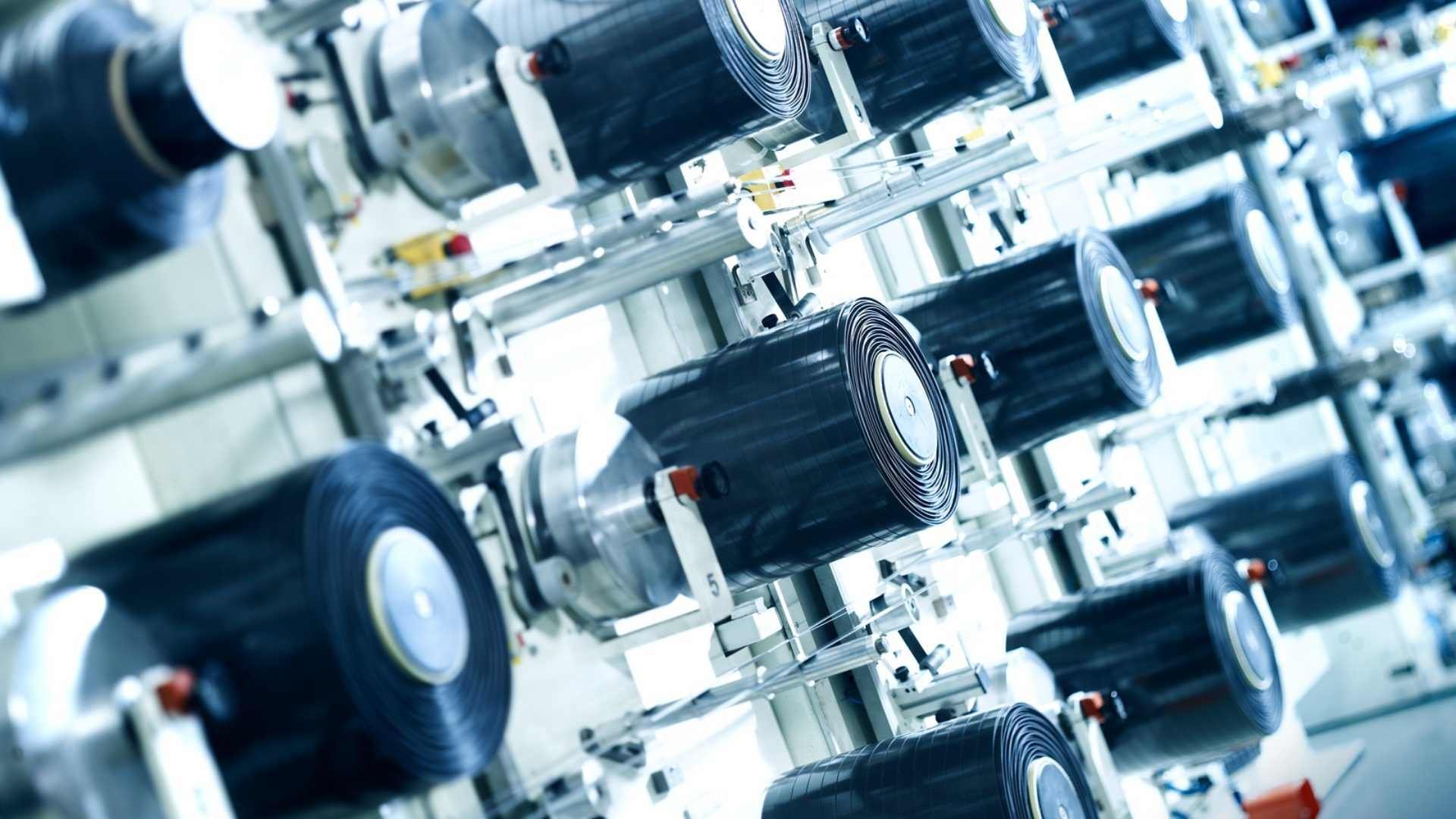

The Engineering Behind the Bond

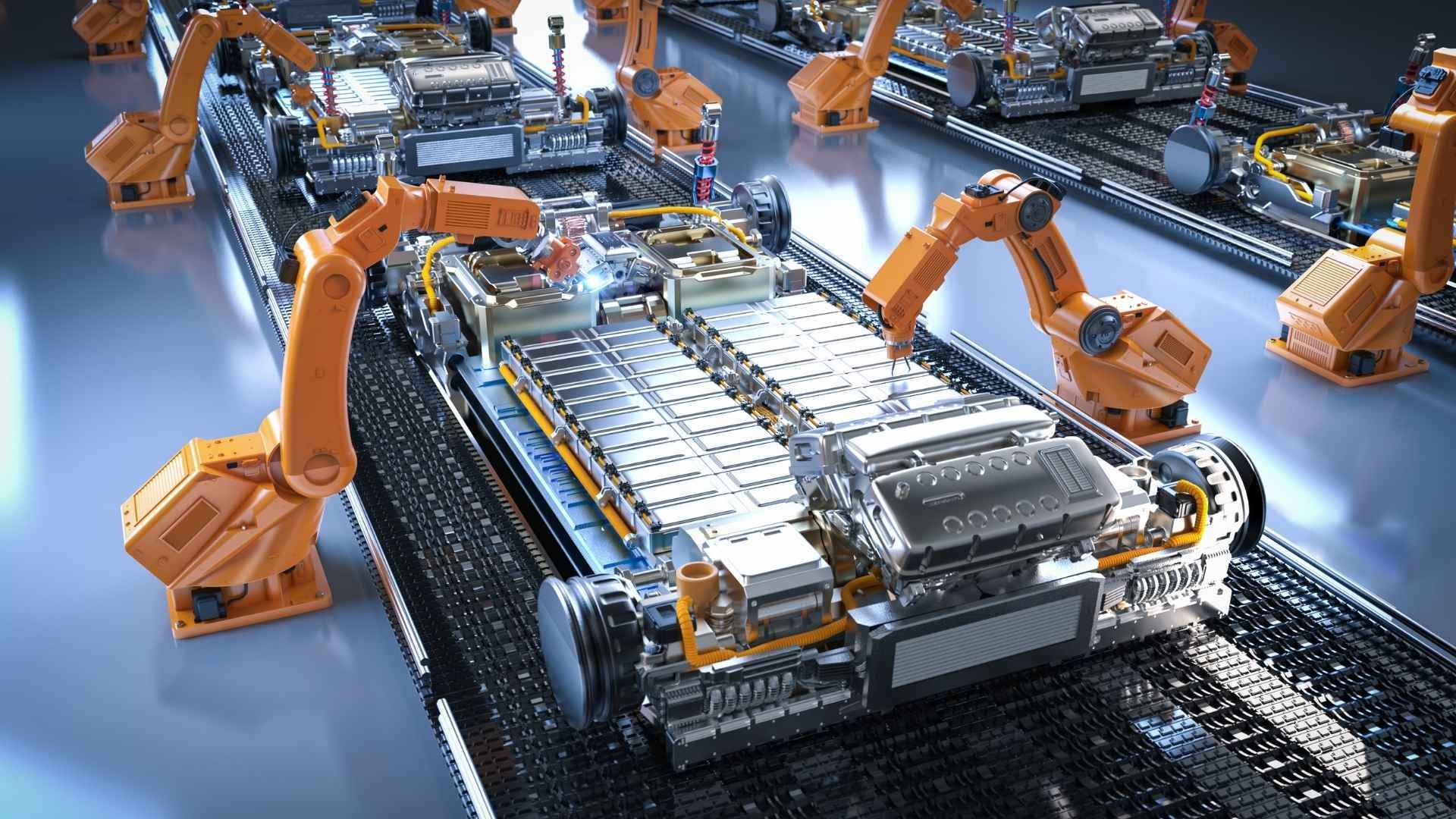

Adhesive technologies are silent enablers of innovation – from bonding lightweight materials in electric vehicles to enabling clean removability in medical applications. At Lohmann, R&D is the driving force: curious, responsible, and application-driven.

By combining chemistry, material science and process innovation, we develop adhesive solutions that meet the demands of tomorrow.

Agile development is our strength – we adapt proven formulations, optimize designs, and turn new requirements into ready-to-use tapes, fast.

From mobility and electronics to medical and industrial sectors, we create high-performance adhesives tailored to your materials, processes, and goals.

With decades of formulation knowledge and digital tools, we accelerate development, optimize VOC levels, improve material behavior and enhance lab workflows.

Backed by over 170 years of engineering expertise, Lohmann delivers advanced adhesive technologies through close collaboration with customers and research partners – often co-developed and seamlessly integrated into high-volume production.

Future-Ready Technologies for Responsible Bonding

We innovate to improve what matters: performance, processability and sustainability. Our R&D teams are constantly exploring recyclable materials, solvent-free systems and functional layers that go beyond bonding. What drives us is not just what's possible – but what makes a real difference in your product and your value chain.

Responsible solutions

in every bond

Integrity and responsibility as a foundation for customers, employees, society and the environment - this is our conviction and the standard by which we measure ourselves. Our focus: Creating sustainable products and business models and leading by example. We firmly believe that economic success and environmental and social responsibility go hand in hand.

Applied Innovation – From Lab to Line

Our R&D doesn’t stop in the lab. We scale innovations reliably – from pilot coating to full production. Working closely with our application and process engineering teams, we make sure your solution is not just innovative, but also scalable, certifiable and fit for industrial integration.

An adhesive tape may look simple. But every layer is the result of deliberate, high-precision engineering: from polymer synthesis and compounding to carrier material selection and liner design. At Lohmann, we master this complexity by aligning mechanical, chemical, and functional properties to your specific application – whether it’s damping, conductivity, breathability or biocompatibility.

Find out more about our industry-specific solutions as well as our production technologies below.

Our Smart Bonding Approach

Our Smart Bonding Approach aims to develop tailored bonding solutions through close collaboration and personalized consulting. From the initial idea, our teams stand by you as competent partners to collaboratively create innovative and sustainable bonding concepts.

Application

Understanding the application conditions is essential to selecting the right adhesive. Lohmann's engineers guide to select the suitable bonding technology.

Product and Production Choice

Tools

Tools and engineering support for manual, semi-automatic, or automatic dispensing, cutting, and more guarantee safe and efficient customers' applications.

Services

Also during the production phase and beyond, providing full supply chain services through to traceability of delivery and processed materials.

Want to See Adhesive Know-How in Action?

Then step into the Bonding Arena – our real-life innovation lab at the TEC Center in Neuwied.

This is where ideas turn into working solutions. Where you test, tweak, and validate adhesive concepts side by side with our experts. From process simulation to 3D microscopy – experience the full potential of our Smart Bonding Approach.

Open Innovation &

Digital Transformation

We actively collaborate with universities, research institutes and high-tech partners to stay at the forefront of adhesive science. Through open innovation, agile project teams and digital development tools, we translate insights into scalable solutions faster than ever before. Advanced data analytics and material simulation are becoming part of our daily work in designing next-generation adhesives.

Our Innovation Hub is fully dedicated to the future: together with startups, we develop smart products, sustainable materials and digital business models that go far beyond traditional bonding.

Let’s bond the future – together.

Ready to explore our R&D capabilities? Get in touch with our technology experts.

Ready for what's next?

Discover how we develop advanced adhesive technologies, align functional performance with sustainability, and deliver reliable solutions for the challenges of tomorrow.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs