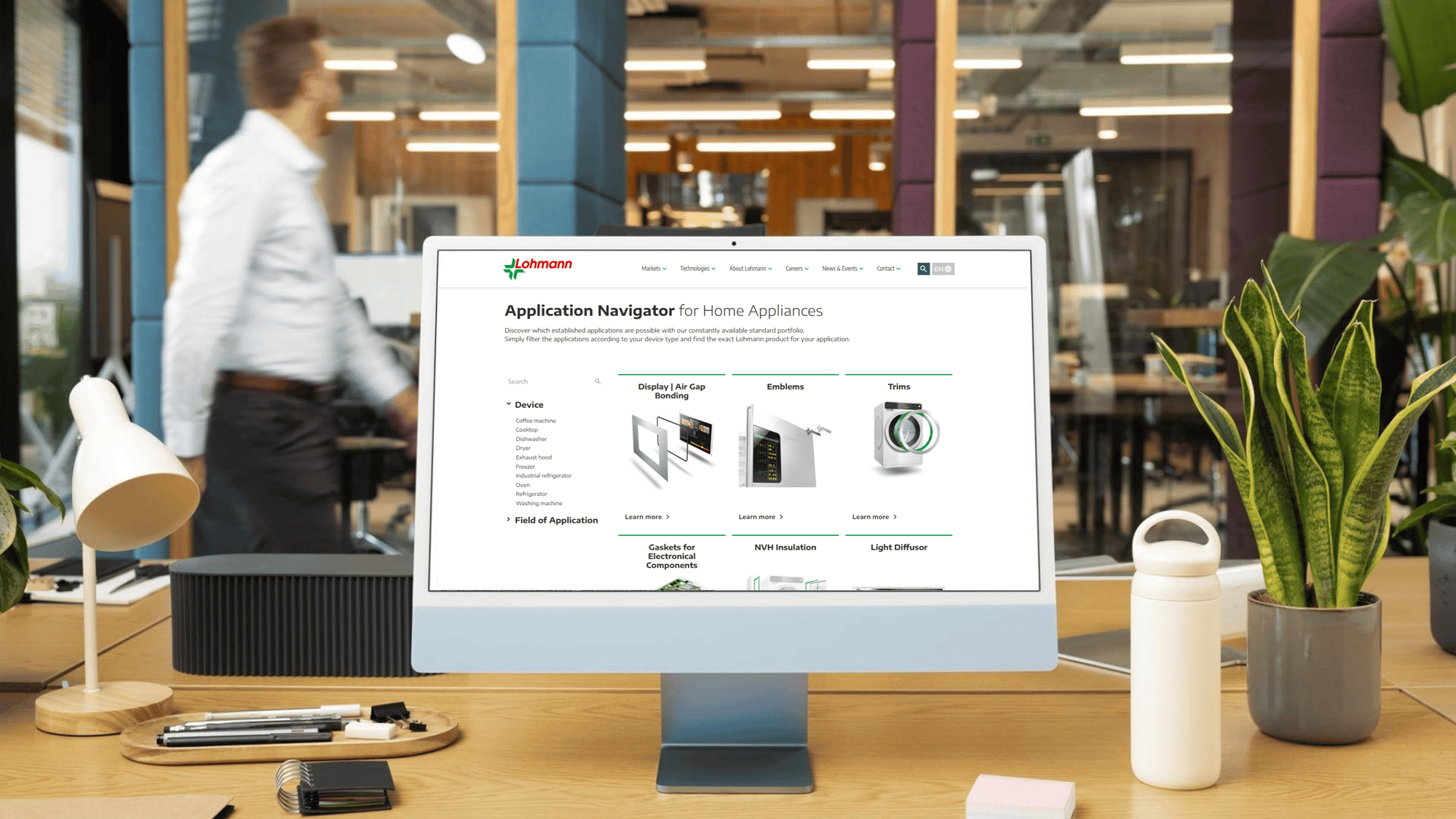

All fields of application at a glance: The Lohmann Application Navigator enables you to quickly and accurately identify the optimal adhesive solutions for your device type. Find the right Lohmann product with just one click!

Bonding Solutions for the Home Appliances Industry

With the commitment to ongoing innovation and the deep understanding of specific performance needs, Lohmann provides solutions throughout the entire value chain – from adhesive tape development via converting to assembly.

Your Reliable Partner beyond Bonding

for Cooking, Cooling, Dishcare and Laundry

At Lohmann, we understand that home appliances play a crucial role in making our lives easier and more convenient, and our product solutions help to ensure that the appliances function optimally. We recognize the diverse range of appliances found in modern homes,

from dishwashers and washing machines to refrigerators, freezers,

ovens, and cooktops. Our expertise lies in offering reliable and customized adhesive solutions and technical expertise that enhance the performance, durability, and safety of these household devices and fit perfectly into the production process for each individual type of appliance and its specific requirements.

Our Focus is on Your Needs:

Adhesive Solutions for every Home Appliances Challenge

Whether single- or double-sided, in rolls or as high-precision die-cut parts: When it comes to the Home Appliances Industry, Lohmann's adhesive technologies fulfill a wide variety of tasks like heat exchange, thermal insulation, resistance to water vapor and other moisture, and sealing against liquids.

Lohmann's adhesive tape applications in ovens, cooktops, and exhaust hoods: front panels, control units, decorative elements, electrical components and more.

Lohmann's adhesive tapes for refrigerators and freezers enable heat exhange, are resistant to water vapor and other moisture, and insulate against noise and vibrations. They make installation easier, shorten production times and increase the design freedom of cooling appliance manufacturers.

Application Navigator:

Find the right Adhesive Solution for your Application

Strong Bonds, Strong Partnerships: From High-tech Tapes to Process Integration

Lohmann is more than just an adhesive tape supplier – we are your strategic partner in developing high-performance bonding solutions for the home appliances industry. To support you in the project phase, Lohmann offers a wide range of testing options. Beside traditional static and dynamic test methods for peel, tack and shear strength, our adhesive specialists conduct various environmental testings for temperature, UV, humidity or chemical resistance. Our product solutions can be integrated into your fully automated processes and enable efficient production. We work together with you to develop the best bonding solution for your individual application and support you throughout the entire project, right up to process integration.

Our Smart Bonding Approach

Our Smart Bonding Approach aims to develop tailored bonding solutions through close collaboration and personalized consulting. From the initial idea, our teams stand by you as competent partners to collaboratively create innovative and sustainable bonding concepts.

Application

Understanding the application conditions is essential to selecting the right adhesive. Lohmann's engineers guide to select the suitable bonding technology.

Product and Production Choice

Tools

Tools and engineering support for manual, semi-automatic, or automatic dispensing, cutting, and more guarantee safe and efficient customers' applications.

Services

Also during the production phase and beyond, providing full supply chain services through to traceability of delivery and processed materials.

PE-Foam Tape Ranges for Various Surfaces

Lohmann offers multiple product ranges of double-sided PE-foam tapes for permanent bonding of add-on parts on different surfaces for Home Appliances applications. The tape ranges are excellently suited for compensating different tolerances of components. They are available as rolls, spools, sheets or die-cuts, depending on the individual requirements.

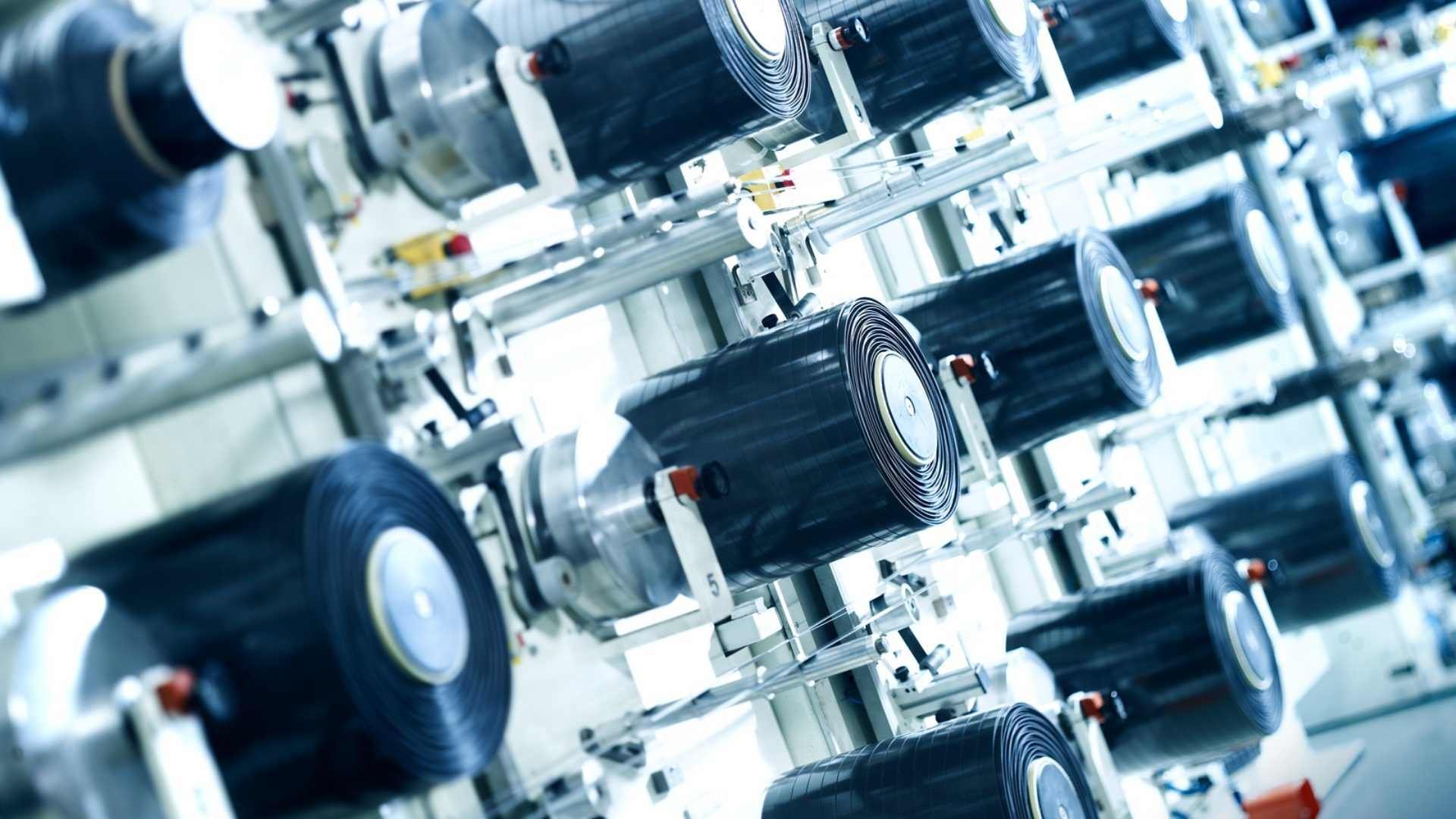

InHouse Converting and Die-Cutting

We convert coated materials inhouse with state-of-the-art converting lines into rolls, spools and sheets in many dimensions or laminate our portfolio to a variety of materials, creating individual product designs.

By using high precision die-cutting machines to produce accurate die-cuts with low µm tolerances, we meet market demands for fine geometries, small dimensions, and various delivery forms, including cleanroom production.

Questions, Ideas, or a Need for Consulting?

Then please feel free to contact us! Our experts are here to assist you with all your inquiries. Whether technical advice, product information, or individual solutions - we are here for you.

Pioneering the Future of Home Appliance Manufacturing

Explore our commitment to developing breakthrough adhesive technologies that shape the future of home appliance manufacturing.

.png?width=767&name=Bilder%20Website%20-%20Marketing%20-%201920%20x%201080%20(3).png)