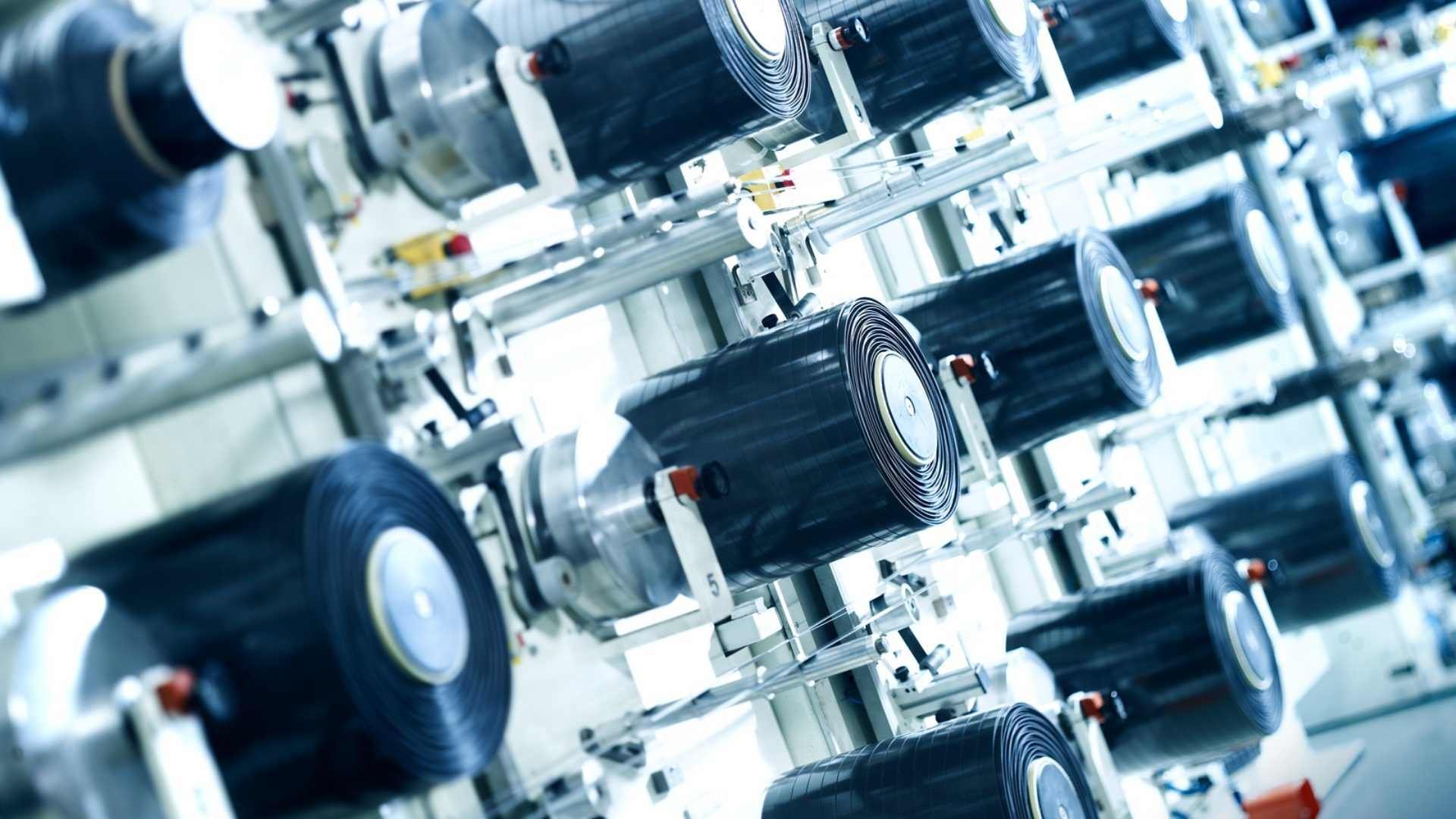

Advanced Production Technologies

Lohmann's state-of the-art manufacturing technologies and precise processing methods make for products of the highest quality - aligned with your specific requirements.

High-Tech Solutions from a Single Source

Lohmann brings deep expertise in developing and executing complex bonding solutions – from concept to full-scale production.

Our fully integrated value chain covers everything: in-house adhesive formulation, prototyping, coating, laminating, converting, precision die-cutting, testing, toolmaking, and even automation-ready solutions. This ensures maximum flexibility, short decision-making paths, and reliable quality – all from a single source, independent of intercontinental supply chains.

Our Integrated Value Chain. Strong Bonds. One Partner.

In our state-of-the-art facilities, we produce high-performance homopolymers – the foundation of every Lohmann adhesive. This is where our value chain begins, with precision, care, and a deep understanding of molecular dynamics. Our in-house polymerization ensures quality from the very first step.

Using advanced extrusion technologies, we process materials such as nonwovens and elastomers into structures with exceptional elasticity. The result? Products that perform reliably under pressure – and adapt perfectly to your application.

On our modern converting lines, we turn coated materials into rolls, spools, or sheets – in your desired dimensions. Thanks to our global network with sites in Europe, America, and Asia, we deliver consistently and close to your market.

Our competence centers operate flatbed and rotary die-cutting machines, full metal dies, laser plotters – and even clean room environments. With tolerances in the low micrometer range, we produce die-cuts in ultra-fine geometries and almost unlimited formats, from holes as small as 0.2 mm to roll-to-roll solutions using "laser-on-the-fly."

From manual to fully automated application tools, we help you implement adhesive solutions with precision. With detailed engineering know-how and practical tools, we ensure that our tapes fit seamlessly into your production.

We tailor each adhesive formulation to your exact needs. Through the smart use of additives, we fine-tune bonding strength and introduce key functionalities – from flame retardancy to UV protection or plasticizer resistance.

We apply acrylic or rubber-based adhesives to carrier materials using solvent-based, water-based (dispersion), or hotmelt systems. For applications that demand more, we use reactive crosslinking to boost mechanical and thermal stability.

We laminate diverse materials to create adhesive constructions tailored to your application, whether for optical insulation, multi-functional layering, or design optimization.

In our modern labs, every product undergoes thorough quality checks. We validate bonding strength, environmental resistance, and functional reliability – so that you can rely on consistent performance under real-world conditions.

Bonding meets automation: Our application technology specialists work with you to integrate Lohmann adhesive systems into your existing processes – intelligently, efficiently, and with future-proof scalability.

Optimized Production Technologies

by Lohmann

Our network fosters flexible and efficient production, independent of intercontinental supply chains. With high-tech laboratories and sophisticated testing methods, we continuously ensure top quality across the globe. From the development of custom adhesives, innovative manufacturing processes - like laser-on-the-fly - to the support during process integration: we accompany you through every phase of your project. Leverage our experience for optimized production processes and cutting-edge bonding solutions in your industry.

At Lohmann, coating is more than a process – it’s precision engineering with purpose. With decades of expertise and state-of-the-art technologies, we create functional adhesive layers tailored to your application. Consistent quality, scalable production, and reliable performance – from lab to large scale.

From Idea to Impact:

Your Full-Scope Bonding Solution

From your first idea to process integration, we are your partner at every step. Whether you need high-tech adhesive tapes, custom die-cuts, or end-to-end support for your production setup, we provide precisely what your application demands. Using advanced technologies like laser plotting, rotary die-cutting, and other high-precision processes, we consistently deliver tight μm tolerances and scalable results.

With our Smart Bonding Approach, you don’t just get a product – you get a solution. Backed by lab-tested performance, automation-ready designs, and personal expert support, we help you streamline production and enhance your competitiveness.

Our Smart Bonding Approach

Our Smart Bonding Approach aims to develop tailored bonding solutions through close collaboration and personalized consulting. From the initial idea, our teams stand by you as competent partners to collaboratively create innovative and sustainable bonding concepts.

Application

Understanding the application conditions is essential to selecting the right adhesive. Lohmann's engineers guide to select the suitable bonding technology.

Product and Production Choice

Tools

Tools and engineering support for manual, semi-automatic, or automatic dispensing, cutting, and more guarantee safe and efficient customers' applications.

Services

Also during the production phase and beyond, providing full supply chain services through to traceability of delivery and processed materials.

Questions, Ideas or a Need for Consulting?

Feel free to contact us! Our expert teams are here to assist you with all your inquiries. Whether technical advice, product information, or individual solutions - we are here for you.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs