- Ideal for small to medium production volumes

- Perfect for larger format materials

- Precise preparation of sheet materials for further processing

- Inline lamination of jumbo rolls possible

- Reliable solution for varied material types and thicknesses

Die-Cutting Excellence

Precision with Vision: Tailored, Certfied Solutions and Seamless Integration - for Every Industry.

Tailored Die-Cutting Solutions - Made to Perform, Built to Last

At Lohmann, we don’t just cut – we create possibilities. For over four decades, our high-precision die-cutting solutions have helped companies around the world turn ideas into reliable, scalable results. Whether in medical technology, electronics, automotive, or smart sensors – we combine our deep engineering expertise with a global mindset and a clear purpose: to support you in mastering complexity with confidence.

With our Smart Bonding Approach we work side by side with you – from the first concept to seamless integration into your process. Precision in the micrometer range? Absolutely. Certified quality? Always. Backed by decades of experience and powered by innovation, our Bonding Engineers develop custom die-cuts that do more than just fit – they make the difference.

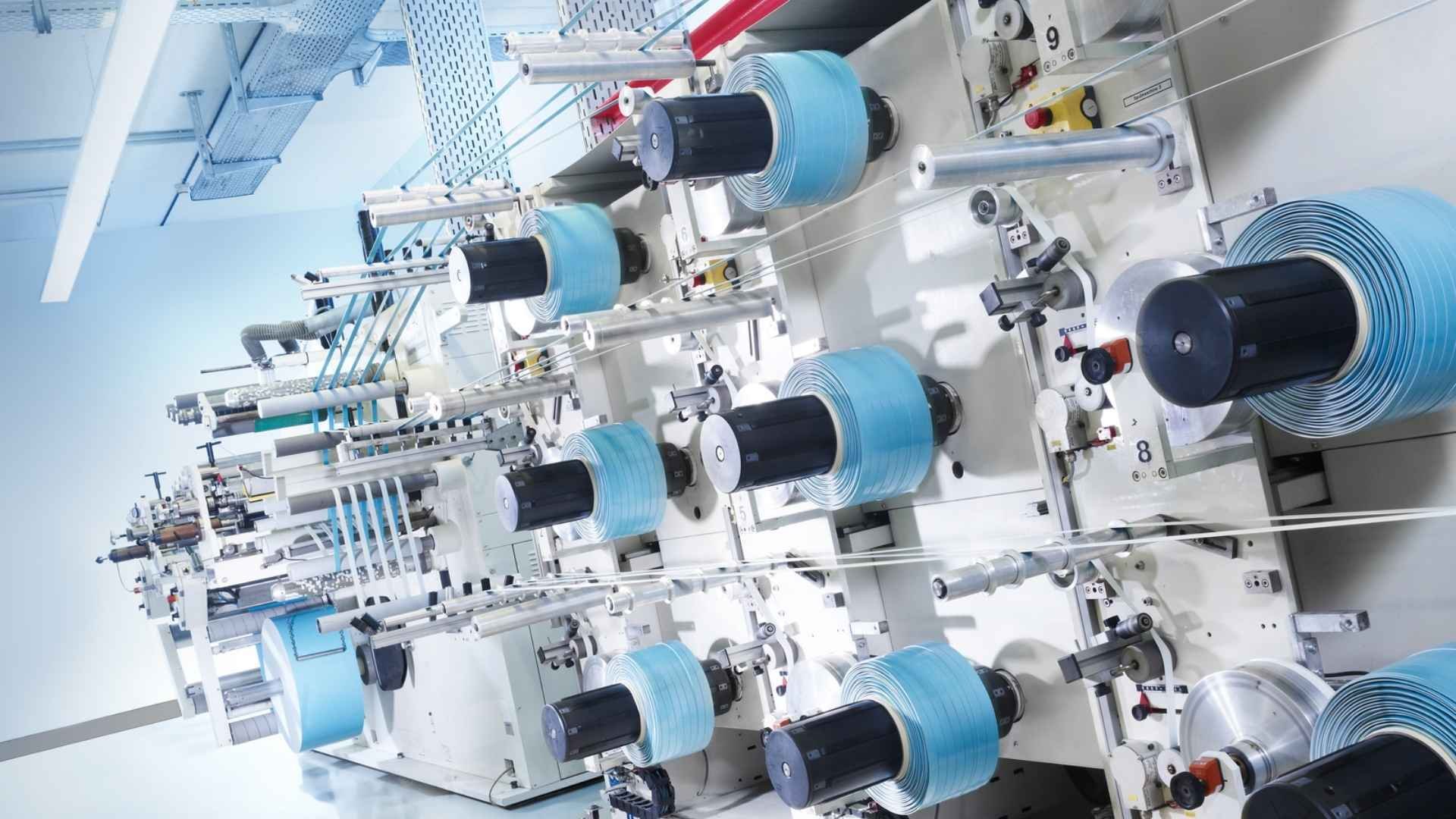

Laser-on-the-Fly: Where Speed Meets Micro-Precision

Innovation is in motion – quite literally. With our state-of-the-art laser-on-the-fly technology, we bring high-speed precision to roll-to-roll processing. This non-contact laser solution enables highly accurate die-cuts, even at full production speed. The result: maximum design freedom, finest geometries, and unmatched efficiency – all in one seamless flow.

Whether it’s ultra-fine holes down to 0.2 mm, intricate channels, or endless format lengths – our laser-on-the-fly process opens up new dimensions in flexible converting. Combined with traditional die-cutting tools, multilayer applications can be implemented effortlessly. No matter the complexity – we’ll find a smart, scalable solution together.

- Continuous roll-to-roll laser cutting with highest precision

- Web widths down to the smallest formats

- Unlimited format length for flexible design possibilities

- Minimum hole sizes from Ø 0.2 mm

- Micro-structured contours and channels made possible

- Compatible with mechanical die-cutting for multilayer setups

- Delivery as roll goods or individual parts

Flatbed

Flatbed die-cutting technology is ideal for processing a wide variety of materials – from paper to plastics to in-mould labeling (IML) – and is particularly effective when it comes to handling smaller volumes or larger formats.

Thanks to its flexibility, flatbed die-cutting is especially suited for packaging, labels, and specialty applications where sheet-fed precision and adaptable formats matter. Whether it’s prototyping or limited production runs – we make sure your cuts are clean, consistent, and integration-ready.

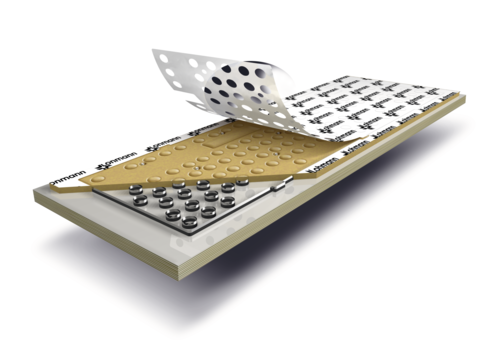

Rotary Die-Cutting

Especially for high-volume production, rotary die-cutting combines speed, precision, and flexibility – even with multilayer materials and intricate geometries.

In rotary die-cutting, a cylindrical die runs continuously in a synchronized system. Multiple stations can be integrated inline – from printing and lamination to measurement and surface treatment. The result? Low tolerances, seamless processes, and a quality that speaks for itself.

Your advantages at a glance:

- Simultaneous processing of multiple layers with different geometries

- Integrated inline measurement and quality control

- Inline printing capabilities (e.g., inkjet)

- Material pre-treatment options (e.g., corona treatment)

- Maximum efficiency for large production volumes

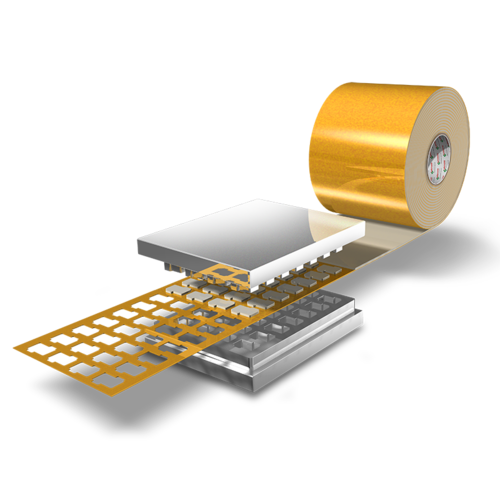

Full Metal Dies

These electromechanically driven systems operate through the relative movement of male and female tools – delivering outstanding results in cutting, embossing, or forming processes.

Especially in short-stroke applications, full metal dies offer unbeatable control. The lifting force can be finely adjusted, and the tolerances are razor-sharp. This technology is ideal wherever consistent pressure, clean edges, and mechanical reliability are a must.

Your advantages at a glance:

- Precise interaction of male/female die sets

- Extremely narrow tolerances

- Adjustable lifting force for tailored application needs

- Reliable performance in short-stroke processes

- Ideal for cutting, embossing, and bending tasks

Laser Plotter Prototyping

Perfect for prototyping and small-volume production, laser plotting technology enables rapid iteration, precise testing, and reliable design verification – with minimal material restrictions.

Operating similarly to flatbed die-cutters, laser plotters excel at marking, cutting, and engraving across a wide range of materials. Whether you're exploring new designs, testing form and fit, or preparing components for pilot runs – this is your agile tool for early-stage innovation.

Your advantages at a glance:

- Ideal for prototyping, model making, and design validation

- Laser-based sheet preparation with high precision

- Efficient for small volumes and fast turnarounds

- Suitable for diverse materials with few limitations

- Clean processing without the need for physical tooling

Your Standards. Our Cleanroom.

Lohmann specializes in high-performance adhesive solutions specifically designed for the medical industry - integrating innovation with cost-efficiency while maintaining precision, stability, and biocompatibility. Whether custom designs or standard products, Lohmann offers solutions tailored to meet individual needs. Comprehensive support is available throughout the entire process, from the initial concept to the final integration, ensuring smooth and effective implementation in medical manufacturing.

In our certified ISO Class 8 cleanroom, we combine engineering excellence with the highest hygiene standards – and have done so reliably since 2014.

Our specially trained experts operate state-of-the-art rotary die-cutting machines (220 mm and 175 mm width) in an environment that includes:

- Controlled access via airlocks

- Strict cleanroom attire (coats, hairnets, shoe covers)

- Meticulous material handling and machine cleaning procedures

- Precise pick & place processes

The result? Tailor-made components that meet the most demanding requirements – with consistency, care, and commitment.

Collaboration for Innovative and

Patient-Centric Medical Solutions

We support medical device manufacturers in co-developing innovative products. Together with SteadySense, we created a non-invasive sensor patch for continuous temperature monitoring – from patient care to ovulation tracking.

Our contribution: development, material selection, die-cutting, and automated packaging – all from one source.

Responsible solutions

in every bond

Integrity and responsibility as a foundation for customers, employees, society and the environment - this is our conviction and the standard by which we measure ourselves. Our focus: Creating sustainable products and business models and leading by example. We firmly believe that economic success and environmental and social responsibility go hand in hand.

Discover the Bigger Picture.

Explore how our manufacturing expertise, innovative spirit, and commitment to sustainability come together – creating real value across the entire Lohmann world.

Questions, Ideas or a Need for Consulting?

Feel free to contact us! Our expert teams are here to assist you with all your inquiries. Whether technical advice, product information or individual solutions - we are here for you.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs