If a cell is overheating the flame barrier material prevents thermal propagation to neighboring cells and therefore helps to keep vehicle passengers safe. Lohmann offers various flame-retardant tape laminations with low thermal conductivity to be used as a flame barrier between cells. At the same time the laminated materials are compressible to compensate the breathing behavior of the cell during charging and discharging and the swelling over the cell lifetime. Lohmann offers customized solutions by combining various materials to match the requirements of different cell chemistries and battery designs.

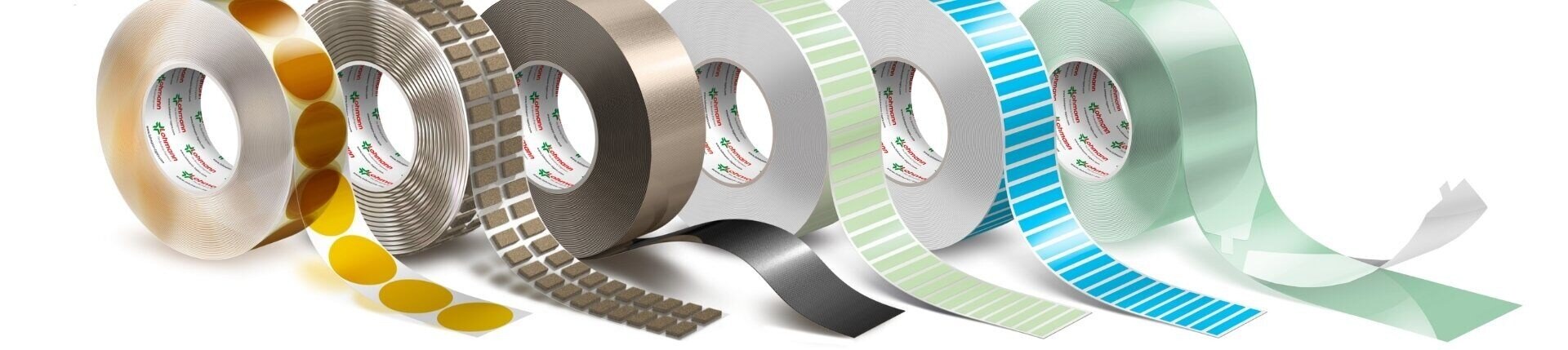

Adhesive Tapes for EV Battery Applications

Smart bonding for reliable and cost-efficient Li-Ion battery assembly. Multifunctional single- or double-sided adhesive solutions on rolls, spools, as sheets, individual laminates or high-precision die-cuts.

Enhancing Battery Performance with Advanced Bonding Technology

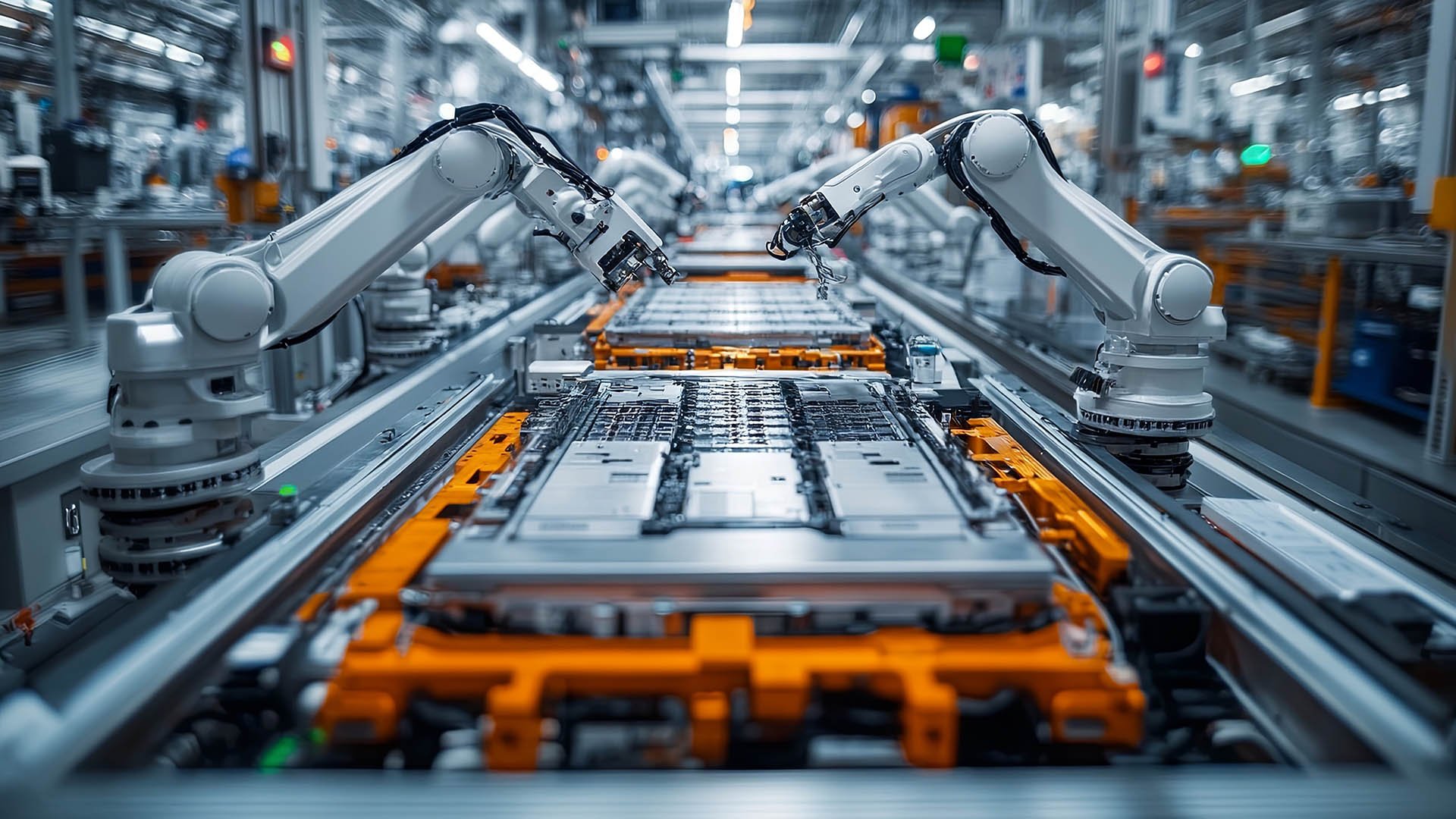

Lohmann provides innovative bonding solutions tailored to the unique challenges of EV battery applications. Designed for seamless integration into modern manufacturing processes, our solutions enhance safety, efficiency, and durability. From prototyping to series production, our global expert teams assist with precision die-cutting, process optimization, and tailored adhesive solutions to meet the highest industry standards.

Extensive High-Tech Portfolio

for EV Battery Manufacturing

Lohmann’s product portfolio of single- and double-sided adhesive tape solutions is available on rolls, spools, as die-cuts or sheets. Lohmann provides customized laminates in a wide variety of materials that combine the individually required properties. In our extensive high-tech portfolio we offer, for example:

- Insulating PET films in various colours and thicknesses, combined with adhesive on one or both sides of the tape.

- PE, PU, EPDM foams or Acrylic Foam in various thicknesses can be combined with adhesive tapes

- Intumescent and thermally conductive materials with self-adhesive finishes

- Electrically conductive fabrics or foams in combination with electrically conductive adhesives

Our products offer smooth thermal or electrical management or serve other functions, such as sealing, damping, virbation and shock absorption, protection or cushioning. The multifunctional tape portfolio offers solutions for numerous applications in Li-Ion battery assembly, for example:

- Busbar protection: single-sided adhesive PET or PI films for the electrical insulation of the busbar

- EMI shielding and grounding: electrically conductive foam tapes as a smart solution for grounding and shielding

- Gasket: Closed-cell PE, PU and EPDM foam tapes for optimal sealing against dust and humidity

- Flame-retardant insulation: Pressure-sensitive tapes can be laminated to various materials to realize self-adhesive flame-retardant insulation

Thermal Management:

Cooling / Heating

Lohmann’s pressure-sensitive adhesive tapes allow an efficient and reliable connection to the cooling or heating element and provide a thermal conductivity of up to 2 W/mK. Tapes from our TC-portfolio support the heat management inside the EV battery and help keeping the lithium-ion cells in their comfort zone between 20 and 35 °C in order to enable the longest possible lifetime of the cells. The double-sided tapes are free of solvents, halogens and silicones and provide effective protection of electrical components as no silicone oil can migrate. All tapes in the portfolio are available on rolls or as customized high-precision die-cuts.

Your benefits

- Thermal conductivity up to 2 W/mK tested according to

ASTM D 5470 - Good adhesion and excellent surface wetting for homogenous heat transfer

- Flame-retardant tapes fulfill requirements according to UL 94 V-0

- Protection against corrosion and abrasive dust

- Different colors available for better detection by vision systems

- Easy assembly thanks to reliable and seamless integration into highly automated production processes

Products

- DuploCOLL TC range (Thickness range: 140 µm - 2 mm)

Electrical Management:

Electrical Insulation

For the electrical insulation of sensitive battery components and effective protection against dielectric breakdown, Lohmann offers various single- or double-sided PET films. They can be applied to metal parts of the battery, e.g., on side panels, cell housing or battery case components. Due to their flexible adaptation to various shapes, they can optimally be used for cell wrapping. For better camera recognition in fully automated production processes, different colors of PET are available to support safe and reliable mounting.

Your benefits

- Optimal electrical and thermal insulation

- Tapes are tested for dielectrical strength

- Long-term heat resistance

- Single- or double-sided adhesive tapes, equipped with a PET carrier

- PET tapes available in various colors for reliable detection by vision systems

Products

- Single- or double-sided PET tapes in different thicknesses and color

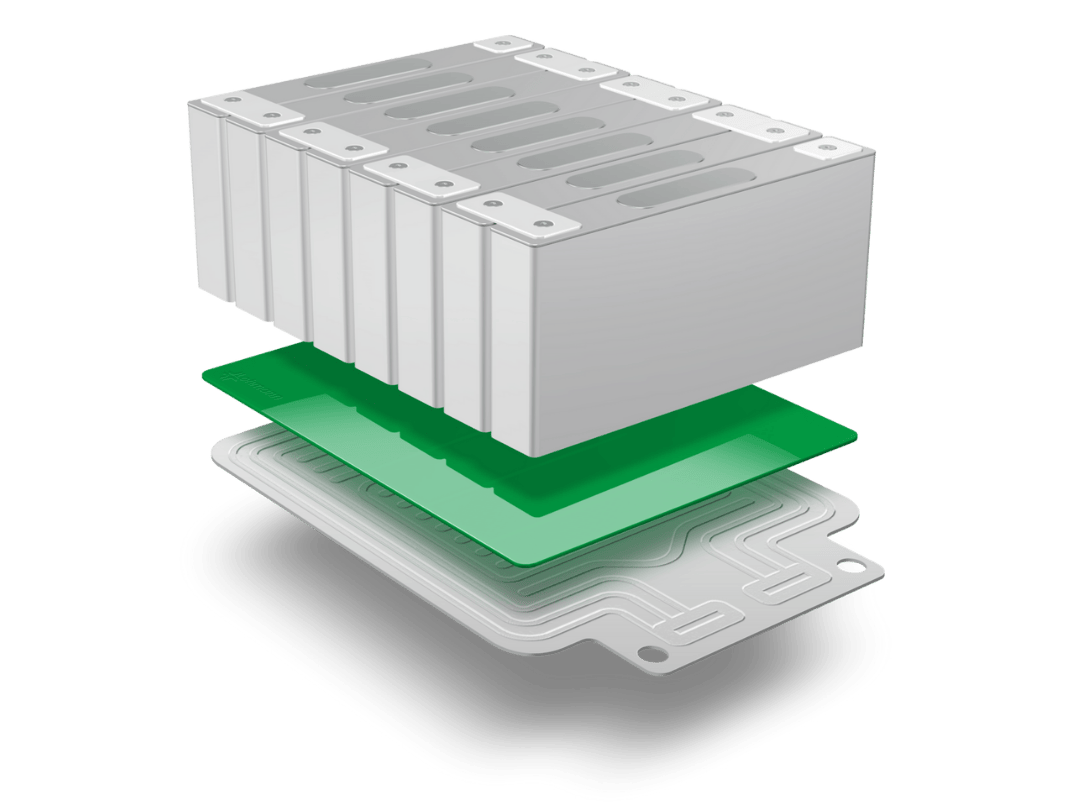

Damp & Seal:

Cell Spacer

The use of foams between individual pouch or prismatic cells as spacer and electrical insulation support the performance of the EV battery. The “breathing” movement of the cell during charging and discharging will be compensated by the foam and generates the ideal backpressure. Foams are also used as spacers between battery packs and support noise reduction management.

Your benefits

- Reliable backpressure for optimal performance of the cells

- Compensation of expansion of cell during use

- Absorption of vibration and shock and thus effective noise-reduction

- Effective cell cushioning due to full-surface bonding of the foam tape

- Compensation of different component tolerances

- Long-term heat resistance

- Electrical insulation properties for protection against dielectric breakdown or flashovers

Products

- Different foam chemistries in a wide thickness range according to individual requirements

Partnership at Eye Level:

Co-Developing

Innovative Solutions

Lohmann is more than just an adhesive tape supplier – we are your strategic partner in developing high-performance bonding solutions for EV batteries. With each new project we focus on the entire production process, ensuring seamless integration into your manufacturing environment. Our experienced international project teams work closely with battery manufacturers and suppliers to understand

the specific challenges of modern battery systems. We provide on-site support, customized specification work, and solutions that meet the highest industry standards, including IATF 16949 certification. At Lohmann, we don’t just supply adhesive tapes – we deliver innovative, high-quality solutions that enhance battery performance, safety, and efficiency.

Application Example:

Battery Monitoring Tape as All-in-One Solution

Lohmann partners with battery manufacturers to develop advanced bonding solutions that go beyond adhesion. Our customized products integrate functional layers, such as electrical insulation, flame barrier laminates, spacer, and sensors, enabling temperature or deformation monitoring. Designed as individual All-in-One solution for seamless integration into high-speed, automated manufacturing processes: highly efficient roll-to-roll processes for pre-integration lead to reduced costs and work steps for battery manufacturers.

Your benefits

- Extensive multifunctional portfolio in various dimensions

- Structural bonding solutions enable higher energy density by facilitating denser cell arrangements (cell-to-module, cell-to-pack, cell-to-body)

- In-house converting expertise: State-of-the-art converting, laminating and die-cutting lines

- Collaborative development: Co-creation of tailored solutions in partnership with customers

- Optimized manufacturing processes: Integration as All-in-One solution into automated production lines with minimal process steps

Products

- Customizable solutions tailored to specific performance and process integration requirements

Questions, Ideas, or a Need for Consulting?

Then please feel free to contact us! Our EV battery experts are ready to assist you with all your inquiries.

Whether technical advice, product information, or individual solutions - we are here for you.

Multifunctional

Tape Ranges

The tapes in our multifunctional portfolio offer smooth thermal or electrical management or serve other functions, such as sealing, damping, electromagnetic shielding or light-blocking, vibration and shock absorption, protection or cushioning. Lohmann‘s multifunctional adhesive tapes are optimized to be customized as die-cut solutions to fit perfectly into your highly automated manufacturing process.

Pioneering the Future of EV Battery Manufacturing

Explore our commitment to developing breakthrough adhesive technologies that shape the future of EV battery manufacturing.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs