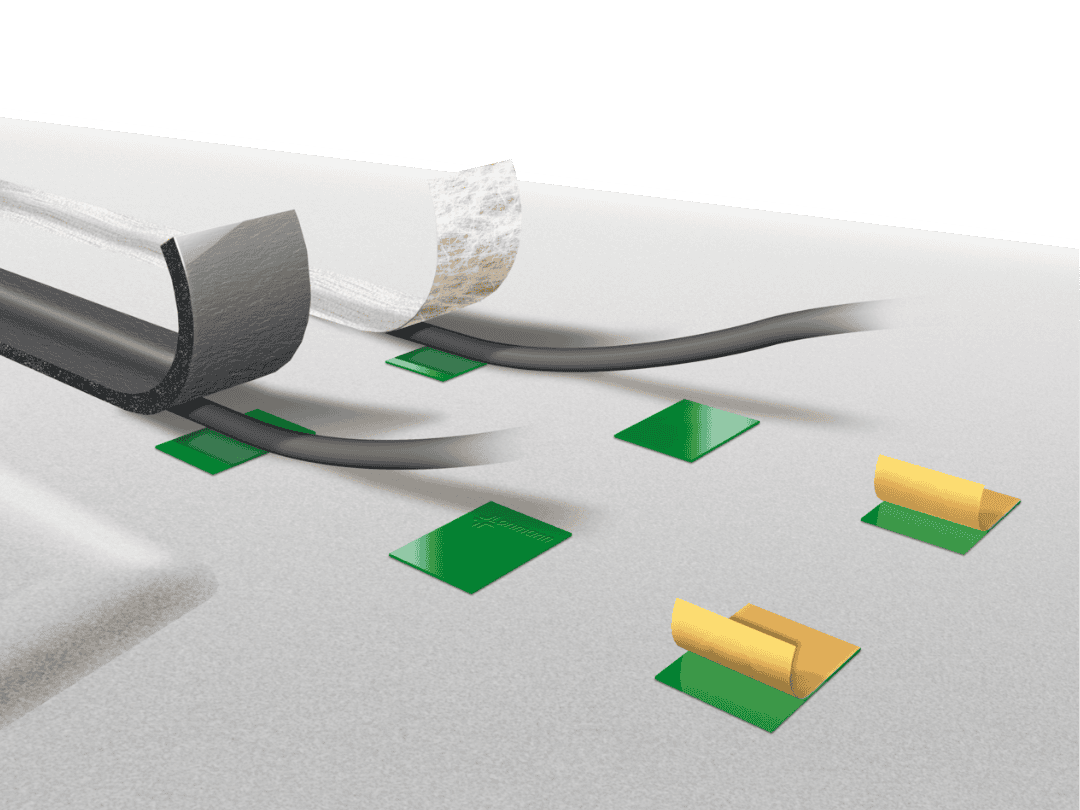

With our foam and non-woven adhesive tapes, cables are reliably fastened to the headliner. The product portfolio answers to the high bonding demands of challenging surfaces and offers effective abrasion protection of round and flat cables. The flexibility of the tapes enables an easy covering process of the wiring harness on the headliner especially in curves.

Adhesive Tapes for Interior Applications

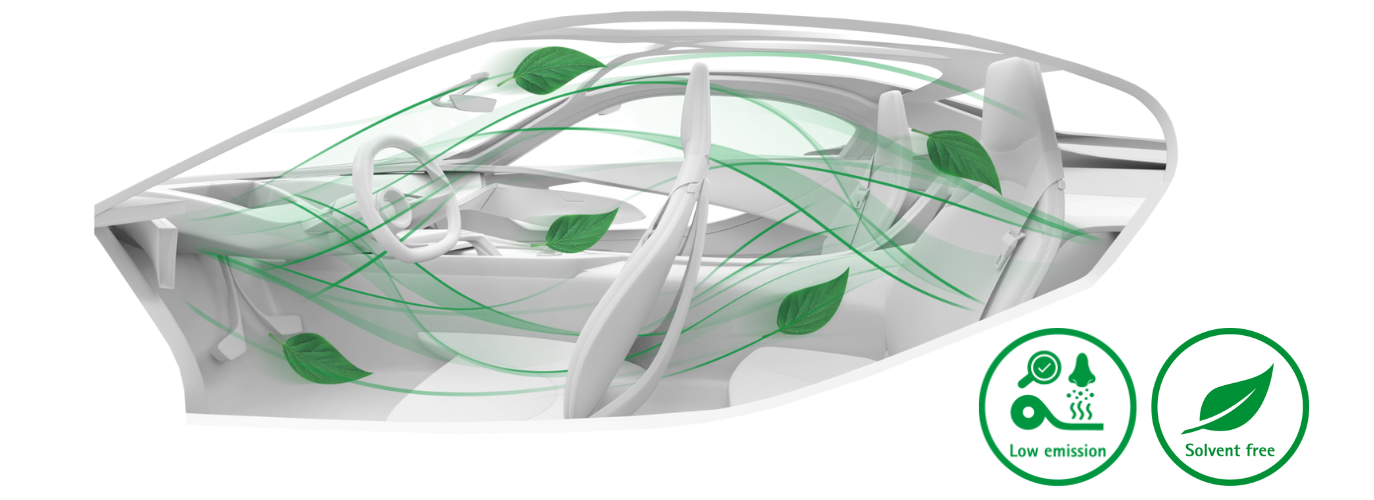

High-tech adhesive tape solutions for low-emission bonding in various automotive interior applications.

Expertise for Low-Emission Automotive Interior Bonding

With a deep understanding of automotive interior requirements, Lohmann offers high-performance adhesive solutions tailored for a wide range of interior applications. Our solvent-free and low-emission tapes ensure reliable bonding of design elements, functional components, and innovative materials – while meeting the industry’s strict standards for air quality, safety, and durability. From headliner applications or decorative trims to seat heating systems, we support OEMs and suppliers with customized adhesive solutions, precise converting, and process integration for efficient and sustainable interior assembly.

Smart Bonding for Modern

Automotive Interior Design

Lohmann’s adhesive solutions are an integral part of modern automotive interior design, enabling reliable and clean bonding of a wide range of materials and components. Especially in the interior, low emissions, high comfort and design flexibility are essential. Our low-VOC tape portfolio meets these requirements while offering excellent adhesion on different substrates including low-energy surfaces..

In addition to their bonding function, our tapes can contribute to noise reduction, compensate tolerances, reinforce or stabilize flexible materials – all without compromising on air quality inside the vehicle.

To ensure maximum efficiency in production, our solutions are available on rolls, spools, sheets or as customized die-cuts – perfectly adapted to the specific requirements of each application.

We offer a broad portfolio of low-emission or multifcuntional adhesive solutions as well as structural bonding solutions for various automotive interior applications, for example:

- Headliner & Roof: cable fastening, microphone or sensor brackets, retainer bonding, NVH felts, acoustic non-woven bonding, crash pads, ambient lighting or in-cabin sensing.

- Doors: NVH felts, decorative panels, ambient light stripes, ambient light (backlit), heating systems, touch displays or intelligent surfaces.

- Seats: heating elements, driver presence detection sensors, leather reinforcement or back seat covers

Headliner | Roof

Cable Fastening

Your benefits

- Effective noise reduction and rattle protection

- Faster production process compared to hotmelt systems (no curing-time)

- No risk of injuries for workers during the assembly process compared to hotmelt systems

- Automatic tape dispenser available on request

Your benefits

- Suitable for many different surfaces

- Excellent noise reduction and rattle protection

- Easy and time-saving application

- Fulfilling OEM cabin air standard requirements due to low-emission and low-odor adhesives

- Solvent-free tapes meet requirements according to VDA 278

- Tape available on rolls, spools, sheets or as customizable die-cuts

Doors

Decorative Elements & Light Stripes

Lohmann's low VOC tapes supports appealing designs by reliably bonding decorative elements, such as carbon-fiber or wood decors, as well as ambient lighting in the vehicle interior. For that, noise-dampening, clean processability and excellent die-cutting properties are essential.

Your benefits

- Wide range of design options for the interior

- Fullfilling OEM cabin air standard requirements due to low-emission and low-odor adhesives

- Solvent-free tapes meet requirements according to VDA 278

- Excellent die-cutting properties allow for individual designs

- Various carrier materials available

- Tape available on rools, spools or as customizable die-cuts

Doors

NVH Felts

Noise-absorbing materials play a major role in vehicle construction, especially for e-cars. The solvent-free adhesive tapes allow fixation of NVH (noise, vibration, harshness) felts to various vehicle parts, such as door coverings. Thanks to low-emission adhesives, even large-area applications do not affect the cabin air quality.

Your benefits

- Excellent adhesion to demanding surfaces and various geometries

- heating-elementsEfficient noise reduction thanks to combination with different damping materials

- Fulfilling OEM requirements for air quality in vehicle interiors thanks to low-VOC and low-odor adhesives

- Solvent-free adhesive tapes according to the specifications of the VDA 278 standard

Heating Elements

Temperature-resistant transfer and scrim adehsive tapes are the optimal choice for bonding surface heating systems in e-cars and heating elements in seats or steering wheels. Lohmann also offers stripe coating solutions to enable seat ventilations as well as tape lamination to individual materials.

Your benefits

- High initial adhesion (tack) for optimized processing

- Excellent adhesion to demanding surfaces

- Low-emission and low-odor even at elevated temperatures

- Solvent-free adhesive tapes according to the specifications of the VDA 278 standard

Your reliable partner for OEM-proven

multi-talented adhesive tapes

In close cooperation with OEMs and tier suppliers, Lohmann's automotive experts are development partners for individual bonding solutions up to serial production. Lohmann produces customer-specific adhesive tapes and converts them into die-cuts. Directly from one source, independently from intercontinental supply chains, in various high-precision manufacturing processes. We offer many years of experience in specification work and are certified according to IATF 16949.

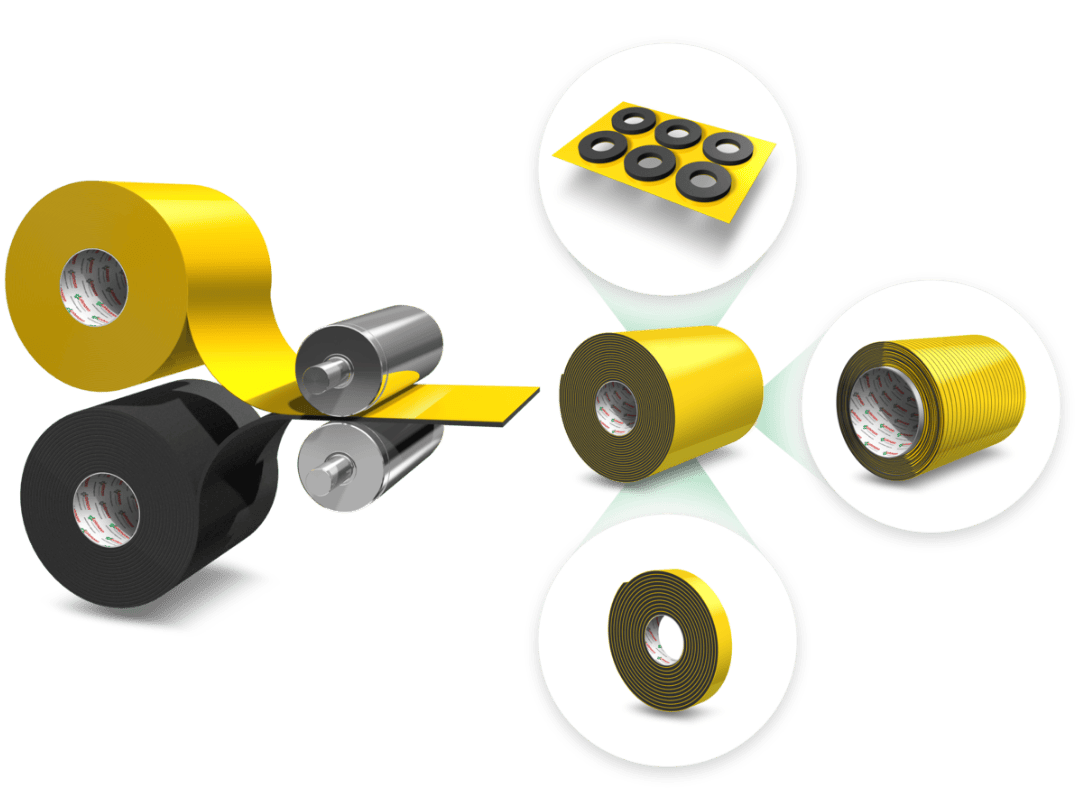

Lamination Toolbox

of Damping Materials

The low-emission adhesive tapes of the DuploCOLL LE range can be laminated with a wide selection of damping materials, including textiles or foams, as well as according to customer requirements. For example, NVH materials such as anti-creak films and felts, damping foams or spacer fabrics can be bonded reliably. These single-sided adhesive damping systems are ideal for noise reduction and sealing for all kinds of décor parts or for fastening cables on the headliner.

The laminated products are available as rolls, spools, sheets or customized die-cuts in every requested format.

Downloadcenter: Datasheets

Download datasheets on our DuploCOLL LE range. The low-emission adhesive tapes for vehicle interior applications are available with 6 carrier materials as well as two liner variations and in different thicknesses.

Technical Product Datasheets DuploCOLL® LE Range

Questions, Ideas, or a Need for Consulting?

Then please feel free to contact us! Our automotive experts are ready to assist you with all your inquiries.

Whether technical advice, product information, or individual solutions - we are here for you.

Pioneering the Future of Automotive Manufacturing

Explore our commitment to developing breakthrough adhesive technologies that shape the future of automotive manufacturing.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs