One Co-Creation Partner.

Full Lifecycle Value.

From design to production to second life – Lohmann combines technical expertise, high-performance adhesive materials, advanced battery monitoring, and debonding-on-demand. Some solutions are proven, others are in development – and the real value emerges when we co-create the complete package together.

Excellence in Every Part. Maximum Success in the Whole.

With the three pillars technical consulting and advanced adhesive technologies, battery monitoring, and debonding-on-demand, you can gain smarter, more efficient, and more sustainable solutions across the entire battery lifecycle. Every component is already powerful, but the maximum value comes from the complete package – supporting design, production, first use, second life, and end-of-life in battery lifecycle.

We look for co-creation partners to bring this concept into practice and deliver lifecycle value from pilot to breakthrough.

Technical Consulting & Materials

-

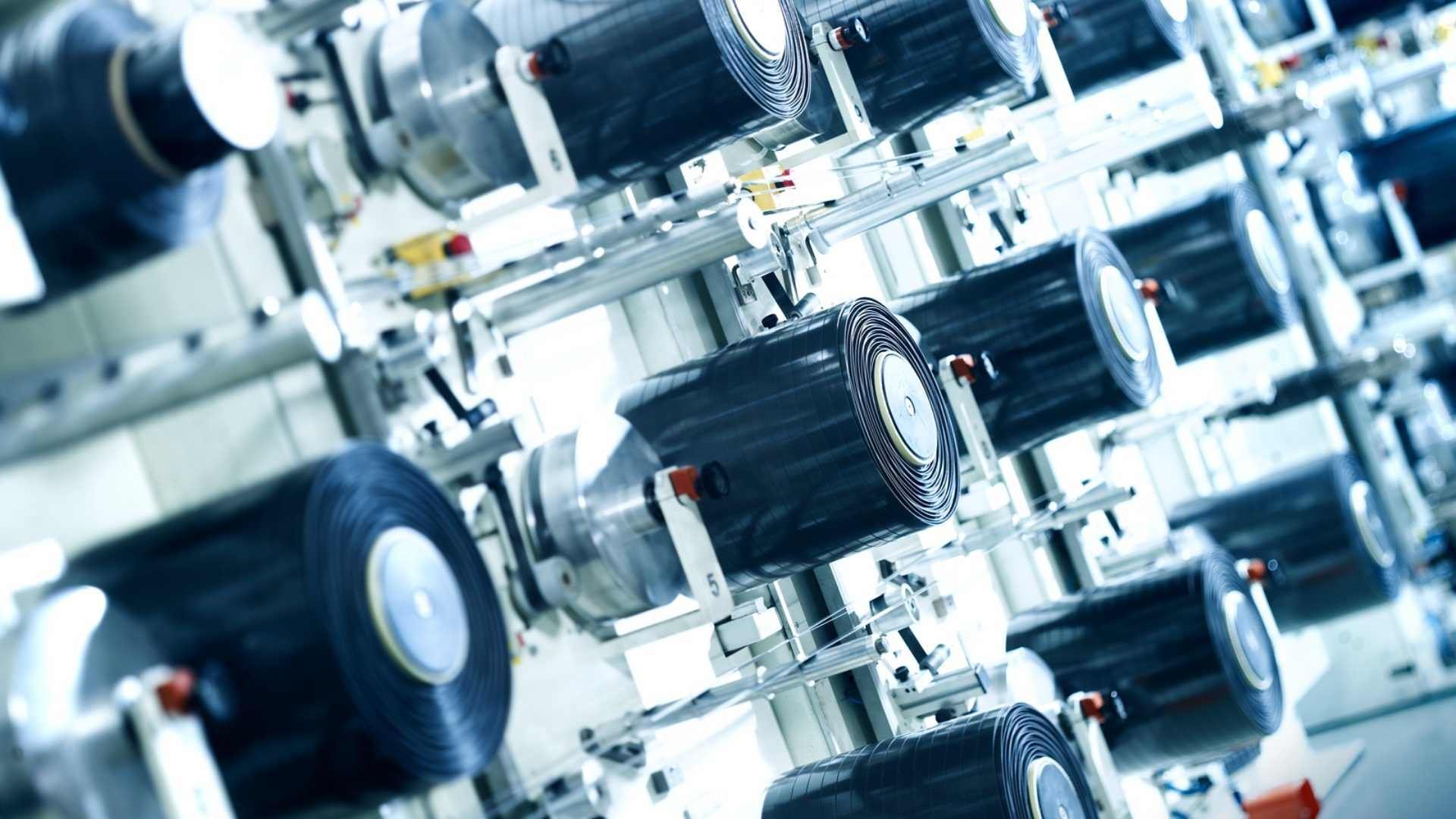

High-tech portfolio of functional bonding solutions

-

Expertise from structural bonding to tailored adhesive systems

Currently available and continuously advanced in co-development projects with partners.

Battery Monitoring

-

Monitoring for cell formation

-

Ensuring safety, quality, and performance

-

Assessment for repair, reuse, and recycling

Offered in pilot projects to drive next-generation monitoring solutions.

Debonding on Demand

-

Rework, repair, reuse, recycling

-

Easy and efficient separation of bonded parts

-

Supporting circular economy

Currently in development – open for co-creation to enable real circularity.

""We combine expert consulting with high-tech materials and technologies – giving our customers tailored bonding solutions that maximize efficiency from the start in production and further phases in battery lifecyle."Pascal Rick, Expert Structural Bonding

Structural Bonding

Technology

Combines the best of two worlds: the benefits of pressure sensitive adhesive tapes and liquid adhesives for crucial benefits in battery lifecycle like improved cost-efficiency, increased process reliability and higher bonding strength.

Platzhalter Wireframe

"Our battery monitoring technologies enables to create measurable value – and together with partners, we are shaping the next level of safety and performance."Dominik Reukauf, Expert Battery Monitoring

Battery Monitoring

Tape Solution

Our battery monitoring tape solution provides optimized process efficiency through highly efficient roll-to-roll processes. These enable a precise pre-assembly of the functional layers as well as the integration of a pick & place sensor

- for best Monitoring-for-Cell formation

- for meeting higher safety requirements and increased performance

- for assessing battery quality, e.g. for repair

"With our debonding on demand solutions, we enable repair, reuse, and recycling – and invite partners to extend these capabilities into true circularity."Tom Schümchen, Expert Debonding on Demand

Debonding on Demand

for efficient Battery Use

Lohmann's Debonding on Demand Technologies integrate durable bonding solutions with the potential of smarter rework, easier repair, maximum reuse and perfect recycling - for real circularity through battery lifetime.

Interested in Partnering for Innovation?

Not all of the innovative solutions are exactly fitted to your requirements - for these purposes we are looking for partners. Together we can pilot, test, and refine solutions that deliver efficiency, functionality, and sustainability across production, first use, second life, and end-of-life to gain maximum value of the complete package. We are here for you.

Pioneering the Future of Automotive Manufacturing

Explore our commitment to developing breakthrough adhesive technologies that shape the future of automotive manufacturing.