Safety, reliability and efficiency over the whole lifetime of the lithium-ion battery and hence the bonded joints are paramount. Lohmann adhesive tape solutions offer a more flexible and weight-saving alternative to mechanical fastening methods, featuring an easy and clean assembly compared to liquid bonding. Using multifunctional tape solutions in the battery manufacturing process combines multiple benefits: They offer immediate and strong adhesion and thus fast handling and add functionality in just one product.

|

|

|

|

|

| Electrically conductive | EMI Shielding | Grounding | Thermally conductive | Flame Retardant |

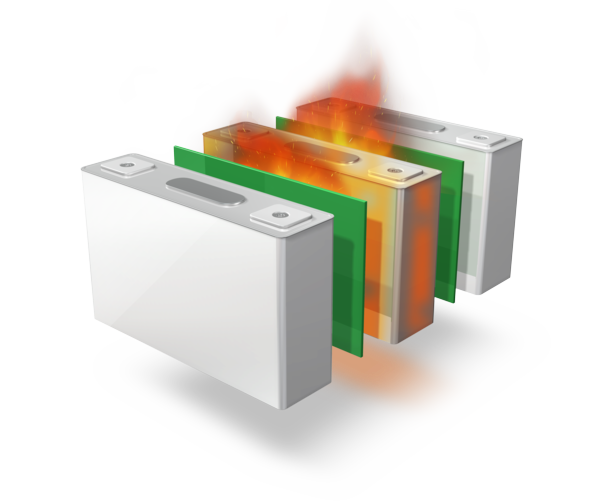

Thermal Management: Flame barrier material

If a cell is overheating the flame barrier material prevents thermal propagation to neighboring cells and therefore helps to keep vehicle passengers safe. Lohmann offers various flame-retardant tape laminations with low thermal conductivity to be used as a flame barrier between cells. At the same time the laminated materials are compressible to compensate the breathing behavior of the cell during charging and discharging and the swelling over the cell lifetime. Lohmann offers customized solutions by combining various materials to match the requirements of different cell chemistries and battery designs.

|

Your benefits

Products

|

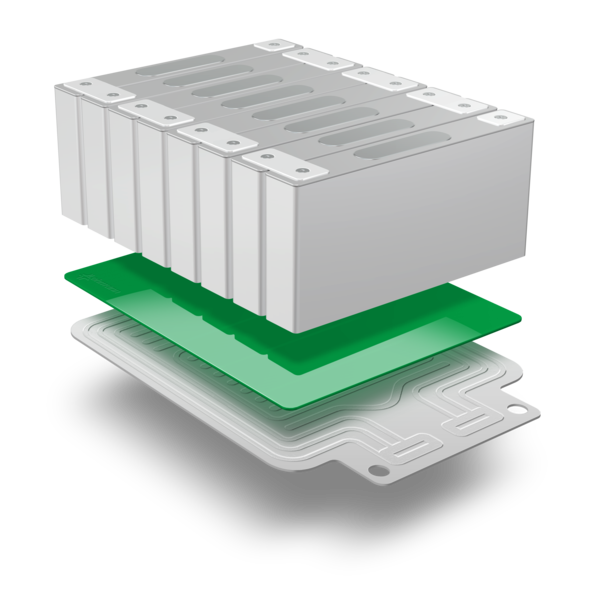

Thermal management: Cooling/Heating

Lohmann’s pressure-sensitive adhesive tapes allow an efficient and reliable connection to the cooling or heating element and provide a thermal conductivity of up to 2 W/mK. Tapes from our TC-portfolio support the heat management inside the EV battery and help keeping the lithium-ion cells in their comfort zone between 20 and 35 °C in order to enable the longest possible lifetime of the cells. The double-sided tapes are free of solvents, halogens and silicones and provide effective protection of electrical components as no silicone oil can migrate. All tapes in the portfolio are available on rolls or as customized high-precision die-cuts.

|

Your benefits

Products

|

Electrical Management: High voltage insulation

For the electrical insulation of sensitive battery components and effective protection against dielectric breakdown, Lohmann offers various single- or double-sided PET films. They can be applied to metal parts of the battery, e.g., on side panels, cell housing or battery case components. Due to their flexible adaptation to various shapes, they can optimally be used for cell wrapping. For better camera recognition in fully automated production processes, different colors of PET are available to support safe and reliable mounting.

|

Your benefits

Products

|

Damp & Seal: Spacer

The use of foams between individual pouch or prismatic cells as spacer and electrical insulation support the performance of the EV battery. The “breathing” movement of the cell during charging and discharging will be compensated by the foam and generates the ideal backpressure. Foams are also used as spacers between battery packs and support noise reduction management.

|

Your benefits

Products

|

|

Our multifunctional adhesive tapes can be used for numerous other applications in Li-ion battery assembly, for example:

|

|

To learn more about the different applications, please download our Application Guide "Adhesive tapes for EV batteries and energy storage":

From the initial idea to the implementation into the final process – from prototyping to series production – Lohmann produces customer-specific adhesive tapes and converts them into die-cuts. Directly from one source, independently from intercontinental supply chains, in various high-precision manufacturing processes (e.g., laser plotter, rotary die-cutting, etc.) and in low μm-tolerances.

Benefit from Lohmann's converting network with numerous locations in Europe, America and Asia. With state-of-the-art coating, converting and die-cutting lines as well as technology centers, the experts in Lohmann's sites worldwide offer you all their know-how in the production and assembly of your individual adhesive solutions and advise you on site.

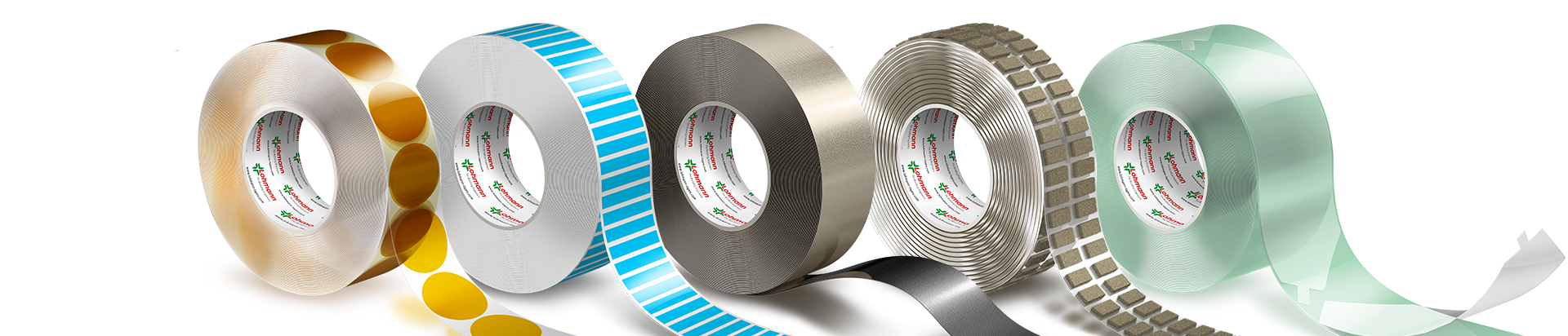

The whole product portfolio of single- and double-sided adhesive tape solutions is available on rolls, spools, as die-cuts or sheets. Lohmann provides customized laminates in a wide variety of materials that combine the individually required properties.In our extensive high-tech portfolio we offer, for example:

To support you in the project phase, Lohmann offers a wide range of tests used in the automotive industry and by OEMs, which are carried out in-house in modern high-tech laboratories as well as in cooperation with external institutes. Beside traditional static and dynamic test methods for peel, tack and shear strength, our adhesive specialists conduct various environmental testings for temperature, UV, humidity or chemical resistance. Furthermore, Lohmann has in-house test equipment for analyzing the conductivity, resistance and impedance of thermal interface materials (TIM) according to ASTM D5470. Apart from process aids such as mounting films or handling aids and simple applicators, Lohmann adhesive technology experts provide additional support for complex manufacturing concepts. To make your fully automated processes even more efficient, our solutions can be integrated reliably and seamlessly, thus enabling high quantity and cost-conscious manufacturing.

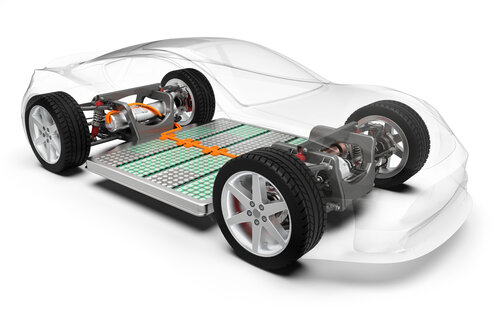

Developments in the electronics sector are driven mainly by digitalization, miniaturization and increased power density. EV batteries become more compact to save weight and combine more cells with a higher energy density to provide higher performance. This leads potentially to more heat generated in the module or pack and more sophisticated battery surveillance and management. Additionally, batteries and further high-voltage components in electric and hybrid vehicles need a reliable electrical engineering including effective protection against electromagnetic waves to prevent interferences as well as smart grounding solutions to avoid short circuits.

These technical challenges continually require new bonding solutions that offer more than just joining components. Our products offer smooth thermal or electrical management or serve other functions, such as sealing, damping, vibration and shock absorption, protection or cushioning. Lohmann‘s multifunctional adhesive tapes are optimized to be customized as die-cut solutions to fit perfectly into your highly automated manufacturing process.

Our portfolio of multifunctional adhesive tapes combines various solutions for electrical and thermal management in Li-Ion batteries. For example:

Please click here to learn more about our Multifunctional Tape Portfolio.

Developments in the battery sector are progressing rapidly. Battery manufacturers are constantly working on identifying alternatives to conventional steel and aluminum housings with the aim of saving weight and improving the battery performance, range and fast charging as well as energy density, cycle life and low-temperature battery performance. The aim is to get the maximum performance out of a battery safely. To support these trends in the field of electric vehicle batteries and the increasing digitalization and miniaturization of systems, Lohmann supplies tailor-made adhesive solutions and high-precision die-cuts.

Read more in our article in the trade journal for industrial adhesives and sealants - adhesion (02/2024):

By choosing Lohmann as your partner you will have access to a highly specialised, experienced and effective team of Battery experts who together with the Lohmann organisation can offer:

Would you like to learn more about our solutions for battery applications or discuss your individual application with us?

Get in touch with us now!

For further information or your enquiries, please send us an email. We look forward to hearing from you!Nicole Ehrmann

Senior Market Manager Transportation