In-House Converting Solutions

From slitting to precision die-cutting, customized laminating and smart engineering: With passion, expertise and innovation, we turn your ideas into sustainable reality.

Turning Ideas Into Precision: End-to-End Converting

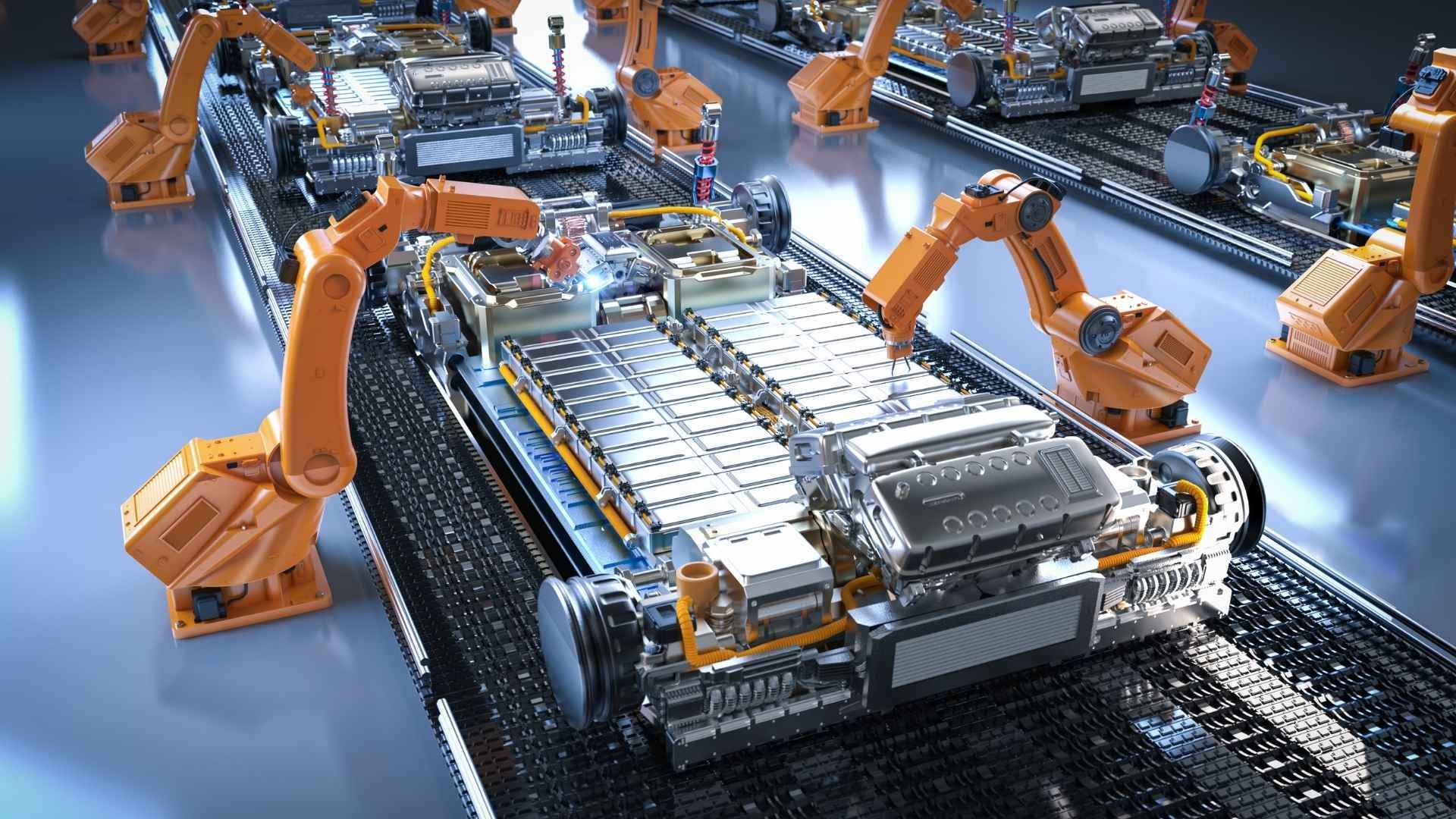

At Lohmann, converting means more than just processing adhesive materials – it’s about delivering smart, reliable solutions that empower your innovation. As your trusted partner at eye level, we offer everything from one source: from material selection to prototyping, scalable production, slitting, packaging, and quality assurance. Whether you require prototypes, small batches, or full-scale manufacturing – we have you covered.

Our capabilities cover the entire production spectrum:

- For prototyping projects (ranging from 1 to 1,000 pieces), we offer individual die-cuts combined with manual assembly, ensuring meticulous quality control at every step.

- Small-scale production (1,000 to 100,000 pieces): Automated die-cutting with semi-automated assembly and robust process monitoring

- Large-scale production (over 100,000 pieces): Highly automated lines, cleanroom capabilities (EU/US), and advanced pick & place integration

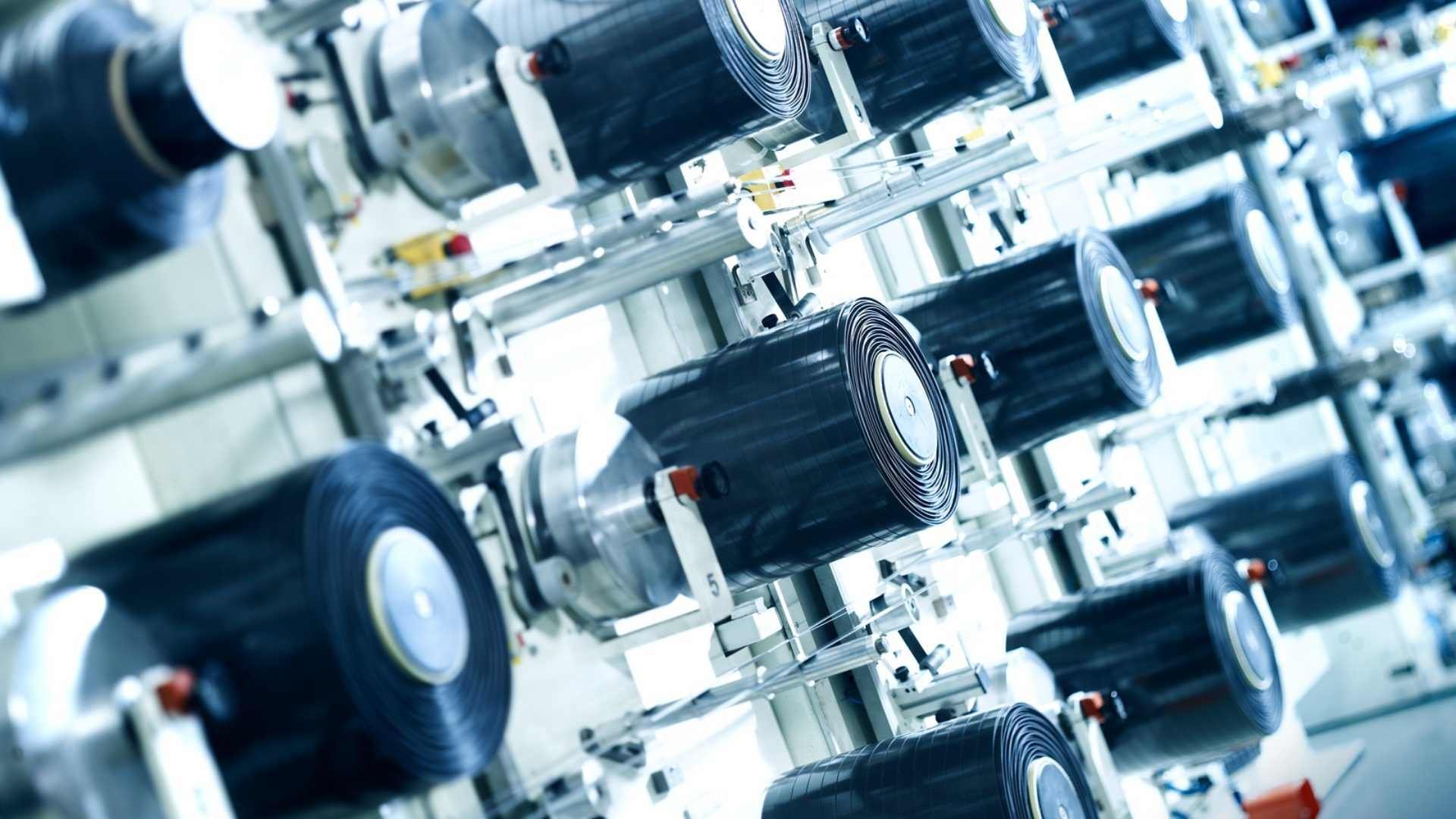

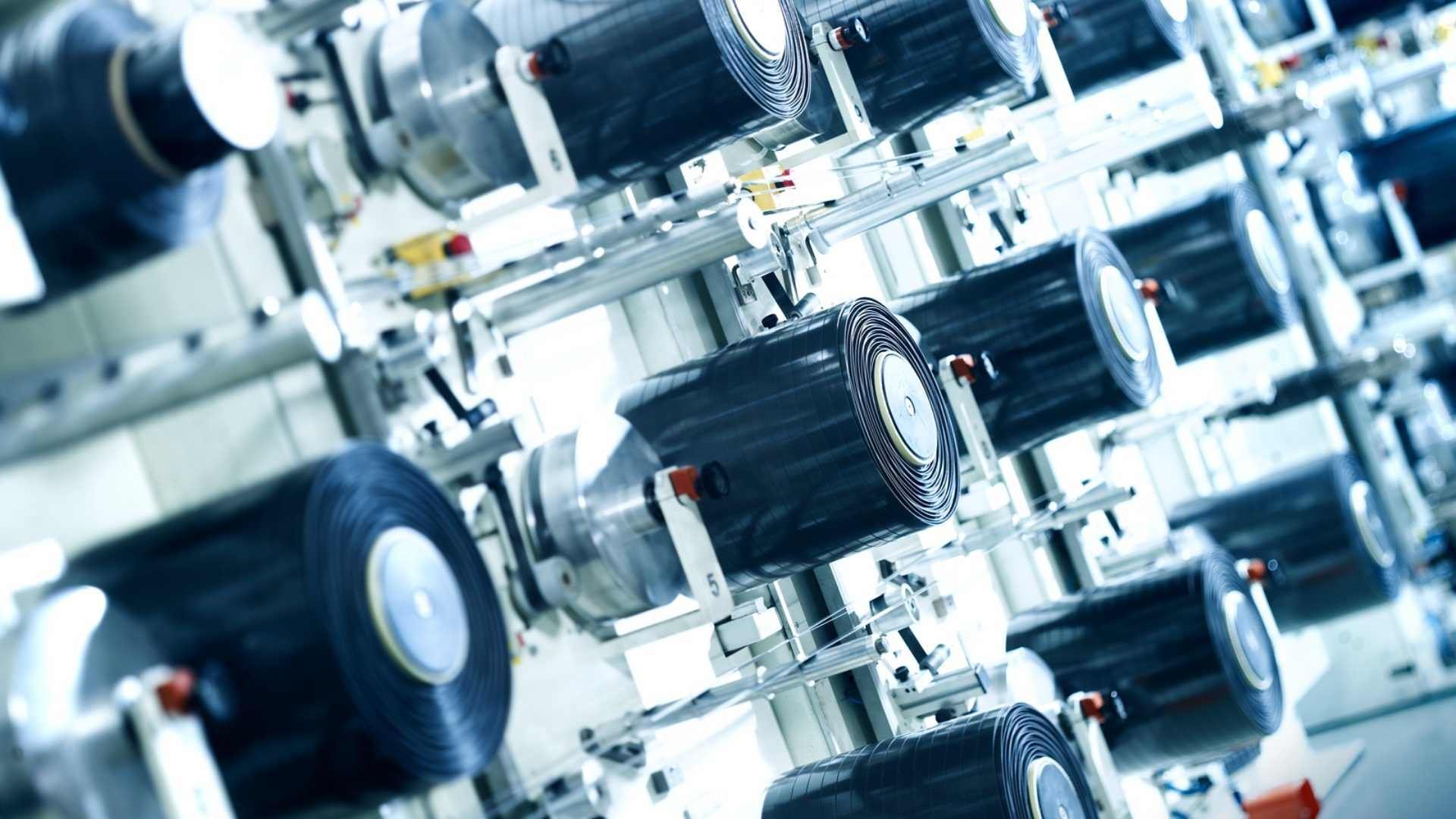

A key part of this process is our high-precision slitting. Whether your material is adhesive-coated or not, our advanced slitting methods ensure every roll is perfectly prepared for your application – manual, semi-automated, or fully integrated into automated production environments. With multiple technologies available, we guarantee clean edges, uniform tension, and consistent performance across a wide range of substrates and formats.

Whatever the volume, whatever the challenge – Lohmann delivers converting precision you can rely on.

Our Slitting Technologies

at a Glance

Ready-to-use. Reliable. Application-specific.

Our slitting capabilities are engineered to provide the best fit for your process – ensuring material performance, reducing waste and supporting high-quality production environments.

.png?width=1280&height=1014&name=LOH_Schneiden_Abstechen_frei_HI_PNG_1280%20(RGB).png)

Lathe / Log Slitting

This high-precision method involves rotating the material on a mandrel while a lubricated circular blade slices it to the desired width. It is ideal for narrow rolls and delivers excellent edge quality – even down to 2 mm widths. Commonly used for adhesive-coated materials.

.png?width=1280&height=992&name=LOH_Schneiden_Klingenschnitt_frei_HI_PNG_1280%20(RGB).png)

Razor Blade Slitting

Perfect for thin, delicate substrates like foils, films, nonwovens, or open-faced adhesive tapes. Material is unwound from a master roll and pulled through stationary blades. Both razor-in-air and razor-in-groove options are available depending on material type and speed requirements. Typical minimum slit width: 20 mm.

.png?width=1280&height=1059&name=Cri8(RGB).png)

Crush / Score Slitting

Using a rounded blade and an anvil, the material is “crushed” apart. This is particularly effective for pressure-sensitive adhesives, as it helps create clean, dry edges. It also works well for diverse substrates including foams, textiles, rubbers and nonwovens. Minimum slit width: 20 mm.

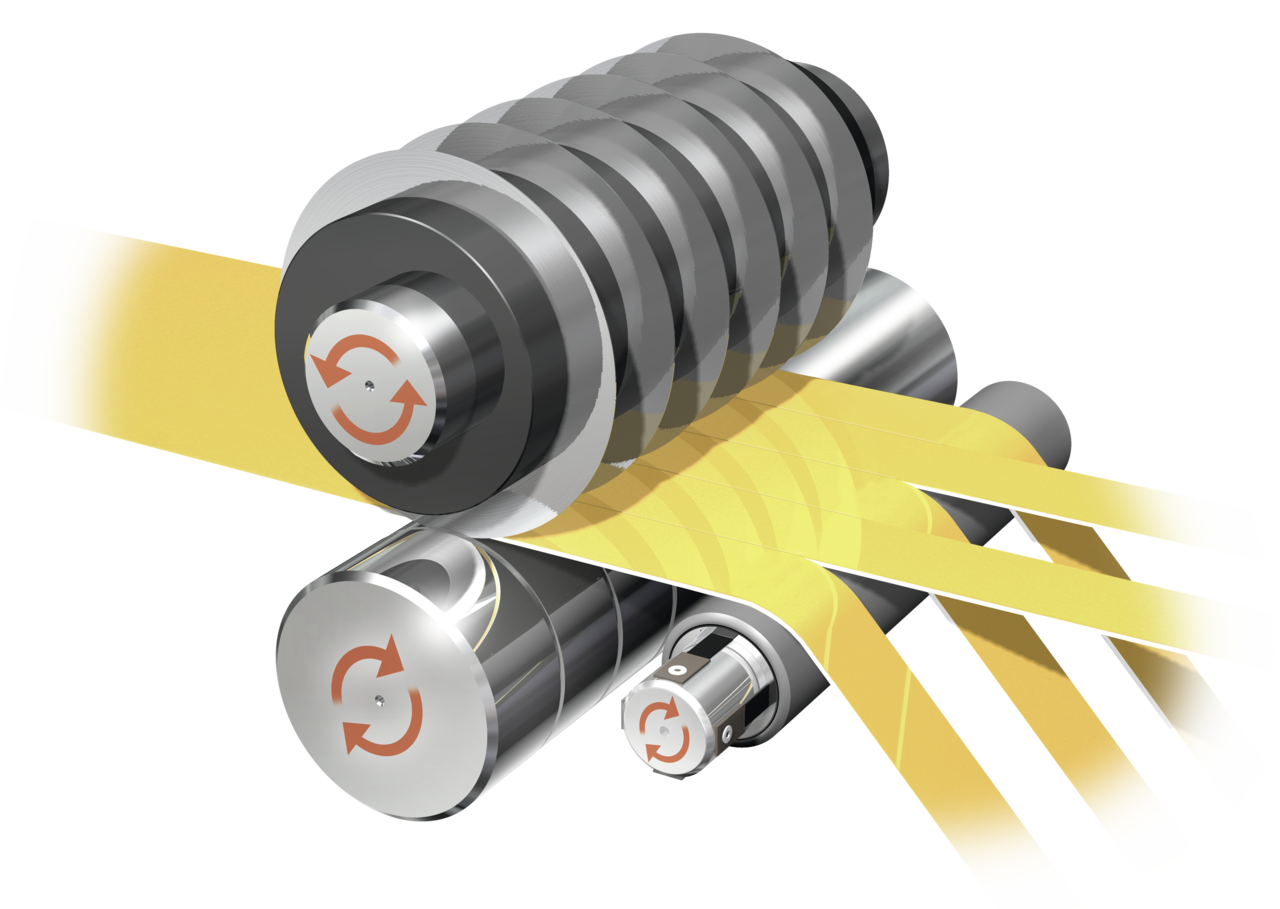

Shear (Scissor) Slitting

This method uses paired rotary blades – male and female – to slice through the material like scissors. It offers minimal dust and excellent edge quality, making it suitable for a wide range of materials: from thin films and papers to tapes and textiles. Slit widths as narrow as 10 mm are possible.

We support you from the idea to its integration into your process.

By choosing Lohmann as a partner you will have access to a highly specialized, experienced and effective Medical team who together with the Lohmann organisation can offer:

- a dedicated project management team

- experience of sourcing, developing and processing high-value functional materials

- a broad die-cutting capability including roll-to-roll flat-bed, rotary, pick-and-place and laser-on-the-fly

- expert in-house testing equipment and test method development

- product development and validation processes tailored to customers requirements

- support of your scale-up

- robust, well documented, traceable and fully auditable processes in accordance with the respective certifications and standards

From Challenge to Solution: How We Make Know-How Count

From industry-specific demands to cleanroom conversion – this is how we translate bonding knowledge into value you can build on.

At Lohmann, we don't believe in off-the-shelf solutions. We believe in understanding your process, your product, and your goals – and combining our adhesive expertise with your specific requirements. That’s what makes our know-how so valuable: it’s built on real projects, real challenges, and real results.

Responsible solutions

in every bond

Integrity and responsibility as a foundation for customers, employees, society and the environment - this is our conviction and the standard by which we measure ourselves. Our focus: Creating sustainable products and business models and leading by example. We firmly believe that economic success and environmental and social responsibility go hand in hand.

Discover the Bigger Picture.

Explore how our manufacturing expertise, innovative spirit, and commitment to sustainability come together – creating real value across the entire Lohmann world.

Questions, Ideas or a Need for Consulting?

Feel free to contact us! Our expert teams are here to assist you with all your inquiries. Whether technical advice, product information or individual solutions - we are here for you.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs