Bonding on Automotive Glass with UV-LUX®

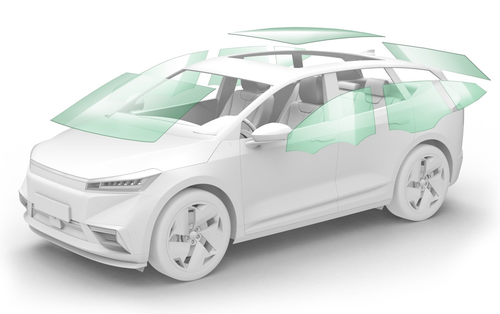

For the bonding of add-on parts to glass in the automotive sector, Lohmann has developed a UV-light activatable double sided tape, that makes the process faster, safer and more sustainable: UV-LUX.

UV-light activatable technology

Innovations have been a Lohmann tradition. In a joint effort with their development partners from the industry, Lohmann has developed an entirely new bonding technology: UV-LUX Technology. The world's first UV-light activatable adhesive tape solution with color change - perfect for

the automotive glazing process. Cold chains and thermal input become obsolete in favor of dark curing. Translucent or thermally resistant materials are no longer needed. In addition to an initial tack, a color change ensures precise, easy and safe manufacturing processes.

Color change for a safe and easy process

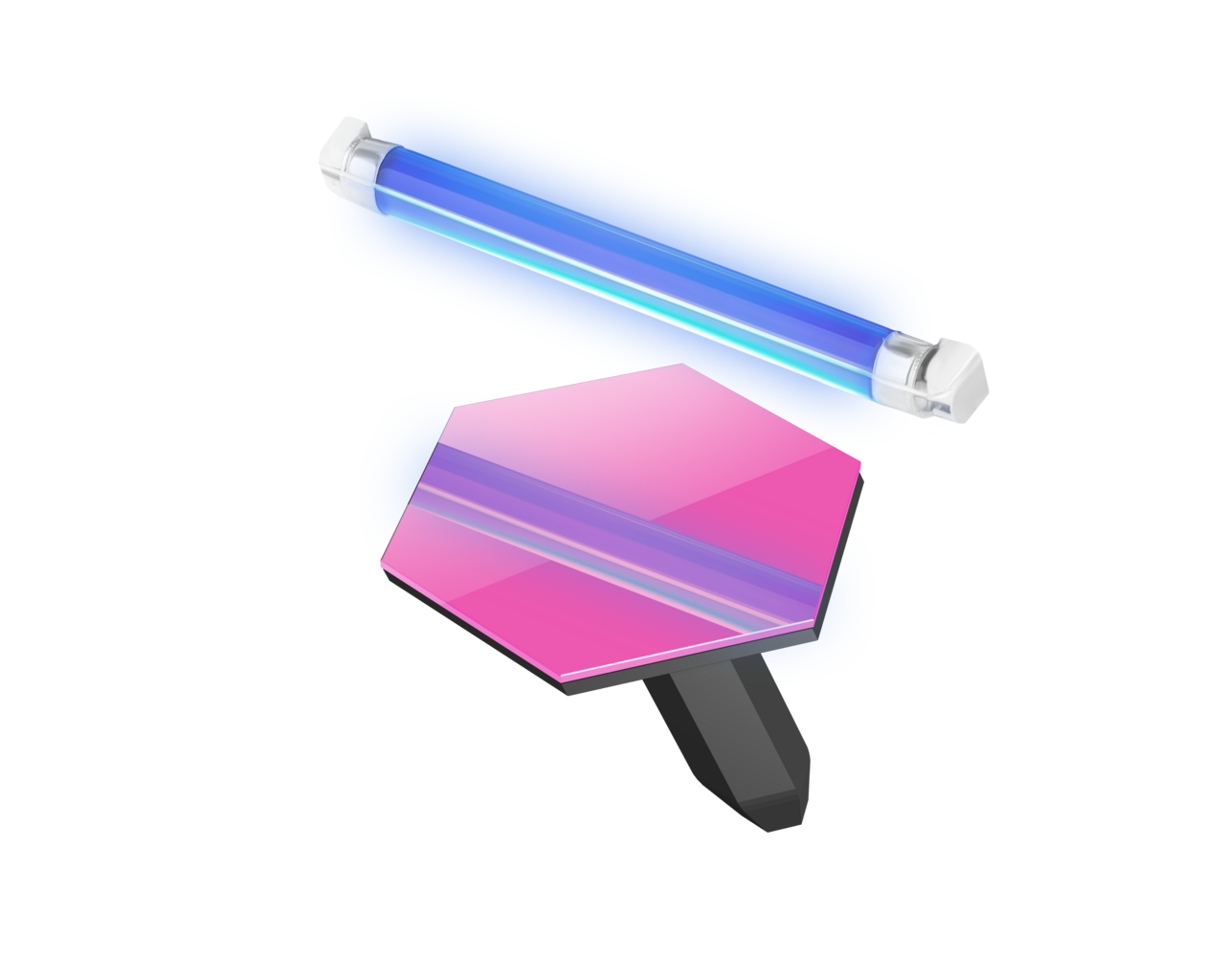

This is how it works: A color change ensures precise, simple and reliable production processes - once successful, activation at a wavelength of 365 nm is made visible by an initial color change on the tape.

Sustainable and efficient bonding processes on automotive glass

For the bonding of add-on parts to glass in the automotive sector, Lohmann has developed a UV-light activatable double sided tape, that makes the process faster, safer and more sustainable: UV-LUX. It combines the fast process of a pressure sensitive tape with the strength of a reactive adhesive.

UV-activation < 3 seconds

No creeping

No pretreatment on glass

By eliminating the need for primers, activators and the cool chain, Lohmann makes processes more efficient and sustainable. Both the short activation time (10 times faster compared to state-of-the-art UV reactive liquid adhesives) as well as the immediate handling strength enable uniquely short process times for a reactive adhesive bond. The semi-structural properties achieved after curing allow heavy parts and glasses to be held in place without sliding or creeping.

Your benefits

- High humidity and aging resistance

The epoxy chemistry gives our products a high moisture and aging resistance to withstand typical industry tests such as PV1200 and Cataplasm. The temperature resistance ranges from -40°C up to 105°C. - Semi-structural strength

Our UV-LUX products combine the ease of use of a pressure sensitive adhesive (PSA) tape with the strength and durability of a semi-structural bond after curing. The semi-structural strength allows our products to require less bonding area to attach a component.

Application example:

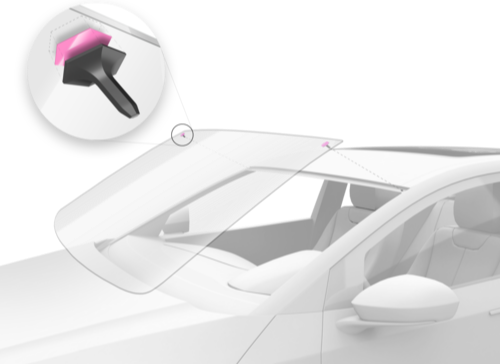

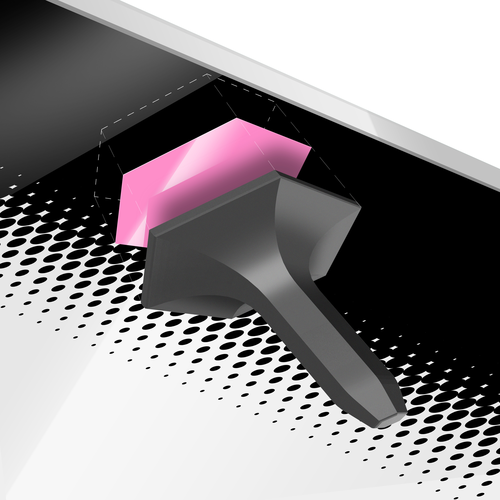

Locator Pin Bonding

To hold the glass in position during the PU-adhesive curing process, Lohmann’s UV-LUX tape provides locator pin bonding with semi-structural strength. The final bonding strength and static shear resistance allows to bond even heavy glasses without creeping or sliding. This allows to enable perfect gap dimensions between the glazing and the car body.

Application process:

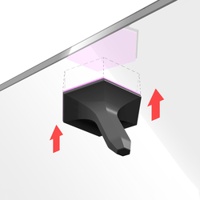

1.

Equipped add-on part with UV-LUX tape and easy liner release through fingerlift

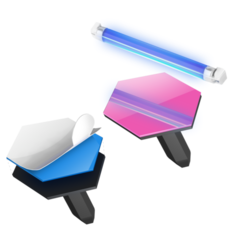

2.

Activation with a 365 nm UV-LED in < 3 seconds and a color change from blue to pink

3.

Application pressure of 20 to 100 N/cm2

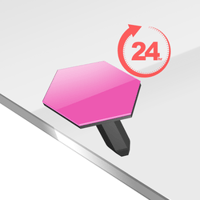

4.

Immediate handling strength, fully cured after 24 h

Activation detection

through color change

A color change from blue to pink initiated by UV-light indicates a sufficient activation and enables a visual check within the process.

Cationic curing mechanism

After activation our tape has an open time of 5 minutes to get applied on the glass. That allows us to bond non translucent attachement parts (i.e. GFRP) to the ceramic frit of the glass.

Delivery of equipped parts

We deliver ready to use add-on parts with a fingerlift option for an easy liner release. This can significantly reduce complexity within your production process.

Your benefit

The Value Chain

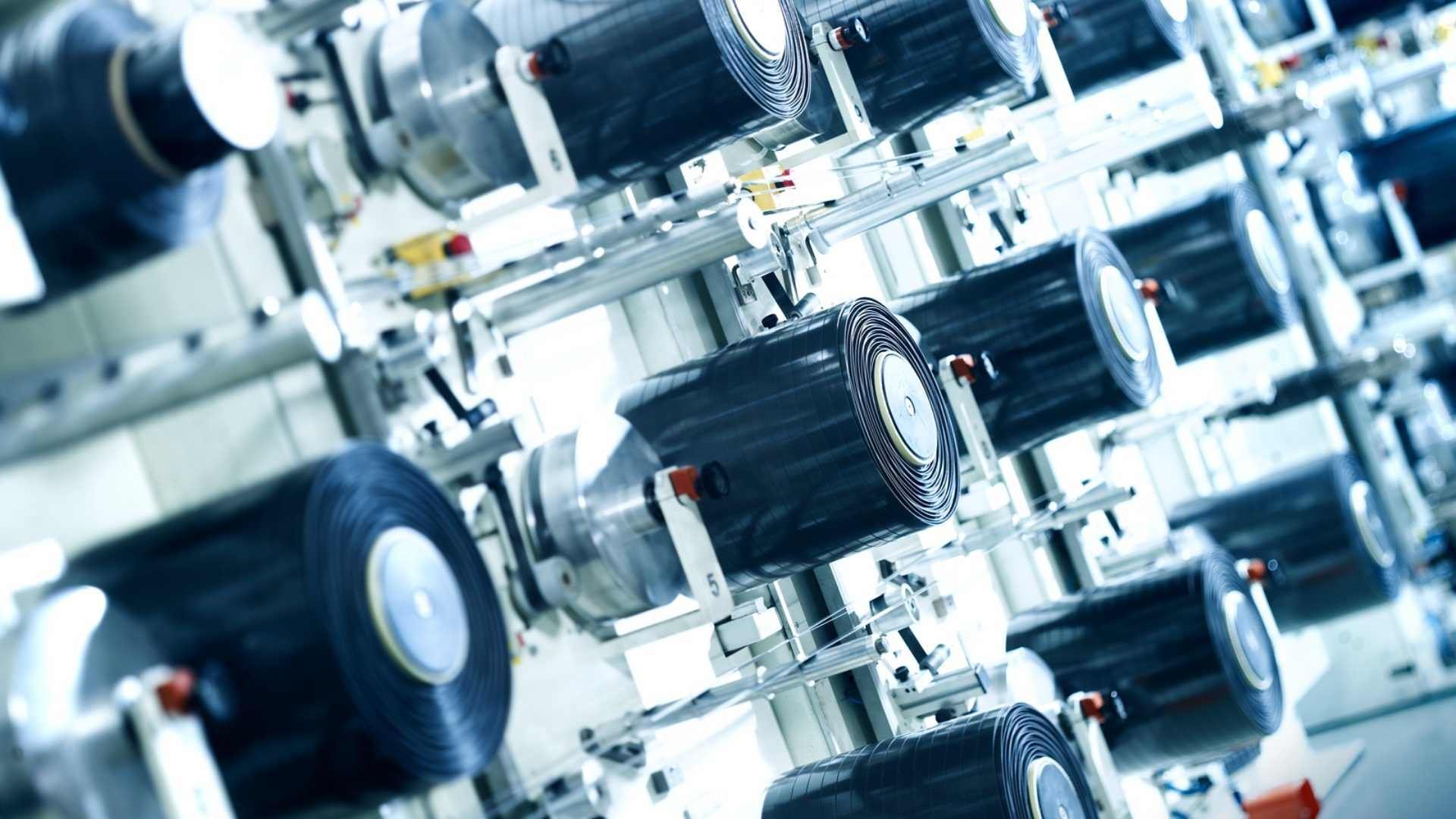

From High-Tech Tapes to Process Integration: Starting from adhesive polymerization to process integration, our state-of-the-art manufacturing technologies and precise processing methods guarantee products of the highest quality and perfectly aligned with your specific requirements in process integration.

Questions, ideas, or a need for consulting?

Then please feel free to contact us! Our UV-LUX experts are here to assist you with all your inquiries.

Whether technical advice, product information, or individual solutions - we are here for you.

Pioneering the Future of Automotive Manufacturing

Explore our commitment to developing breakthrough adhesive technologies that shape the future of automotive manufacturing.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs