Bonding Arena® Where Ideas Take Shape

At the intersection of performance, sustainability and partnership – this is where the future bonds.

Welcome to the Bonding Arena®

Innovation Meets Application

Since 2016, our Bonding Arena at the TEC Center in Neuwied has been the place where ideas become real solutions. On 300 m², we bring together state-of-the-art technology, hands-on application know-how, and cross-functional expertise – from engineering and business development to product management and training.

But more than anything, the Bonding Arena is a space for collaboration.

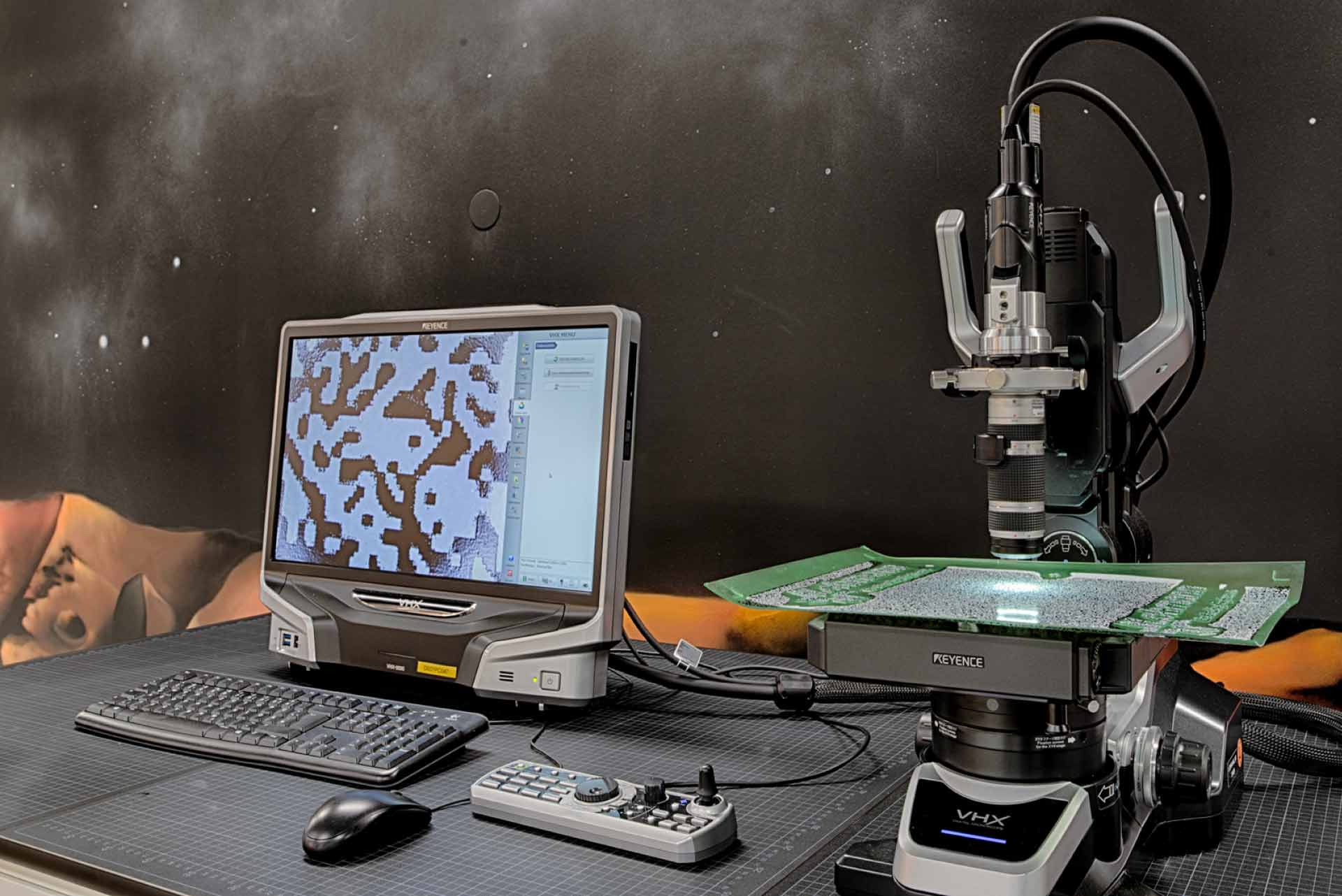

Whether you arrive with a specific bonding challenge or just a bold idea – together, we’ll explore the smartest path forward. Across interactive workstations – from the Smarttester to printing simulation and 3D microscopy – we test, adapt, and refine your solution in real time. Along the way, you’ll experience not just our full value chain, but also our Smart Bonding Approach: responsible, efficient, and always tailored to your needs.

Discover Our Bonding Arena® Stations

Innovation becomes real when it’s hands-on.

In our Bonding Arena, you’ll find a unique combination of advanced technologies, expert knowledge, and practical experience - all brought together at interactive workstations.

Each station is designed to test, refine, and realize your bonding solution - from first analysis to final validation.

Your starting point for smart bonding solutions: At our workstation, a wide range of standard products is ready for you.

Together, we make the first selection for your substrate - or develop a customized solution tailored exactly to your needs.

In our Bonding Arena, we test your bonds under real-world conditions - smart, customer-specific and application-driven. With the Smarttester, we simulate loads like sealing performance or dynamic impulse resistance.

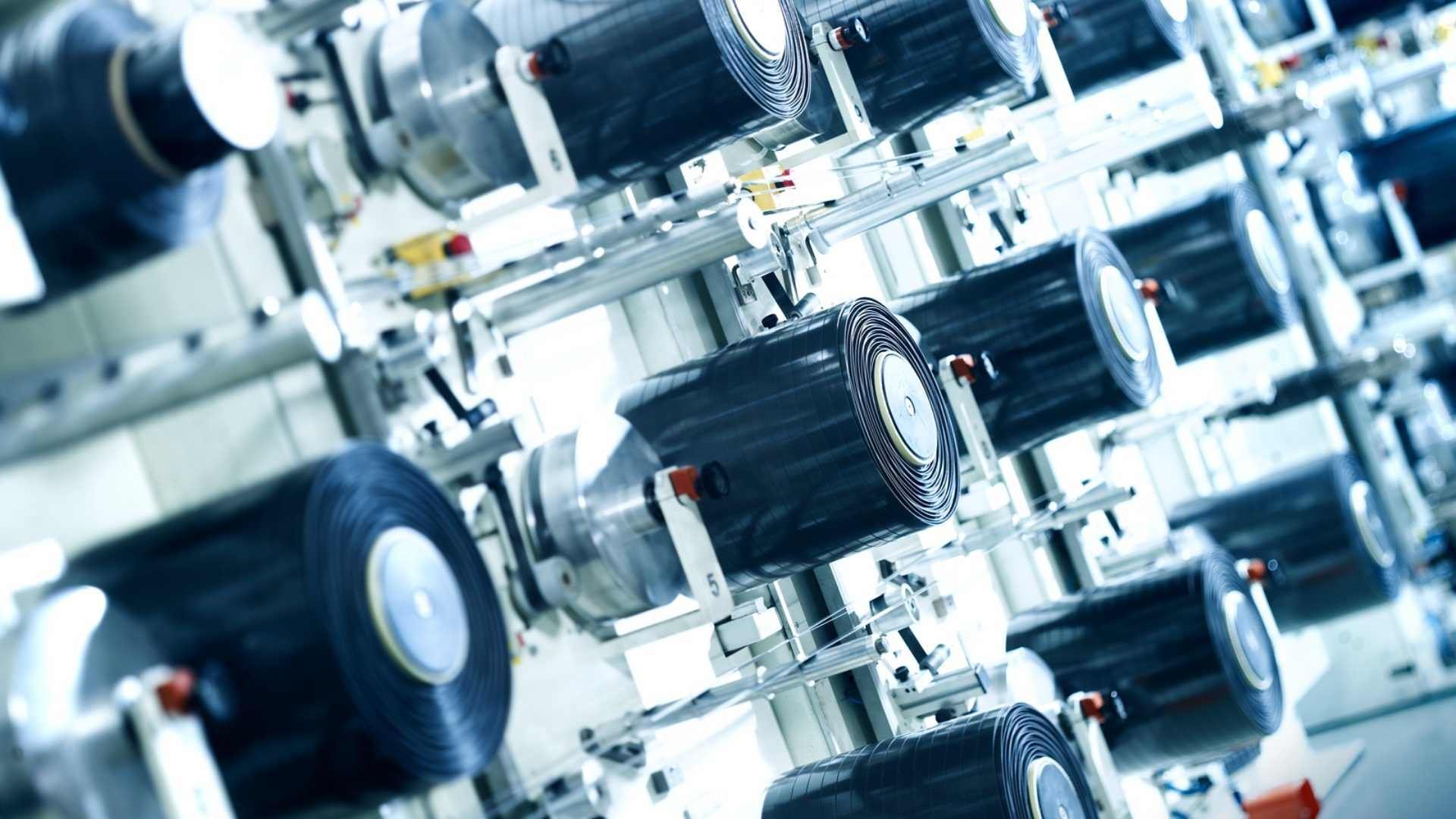

Our Bonding Engineers use the laminator to flexibly create prototypes and samples - fast, precise, and tailored to your needs. We can laminate two materials directly from the roll, with a total thickness of up to 10 mm. Even heat-activated adhesive tapes are no challenge.

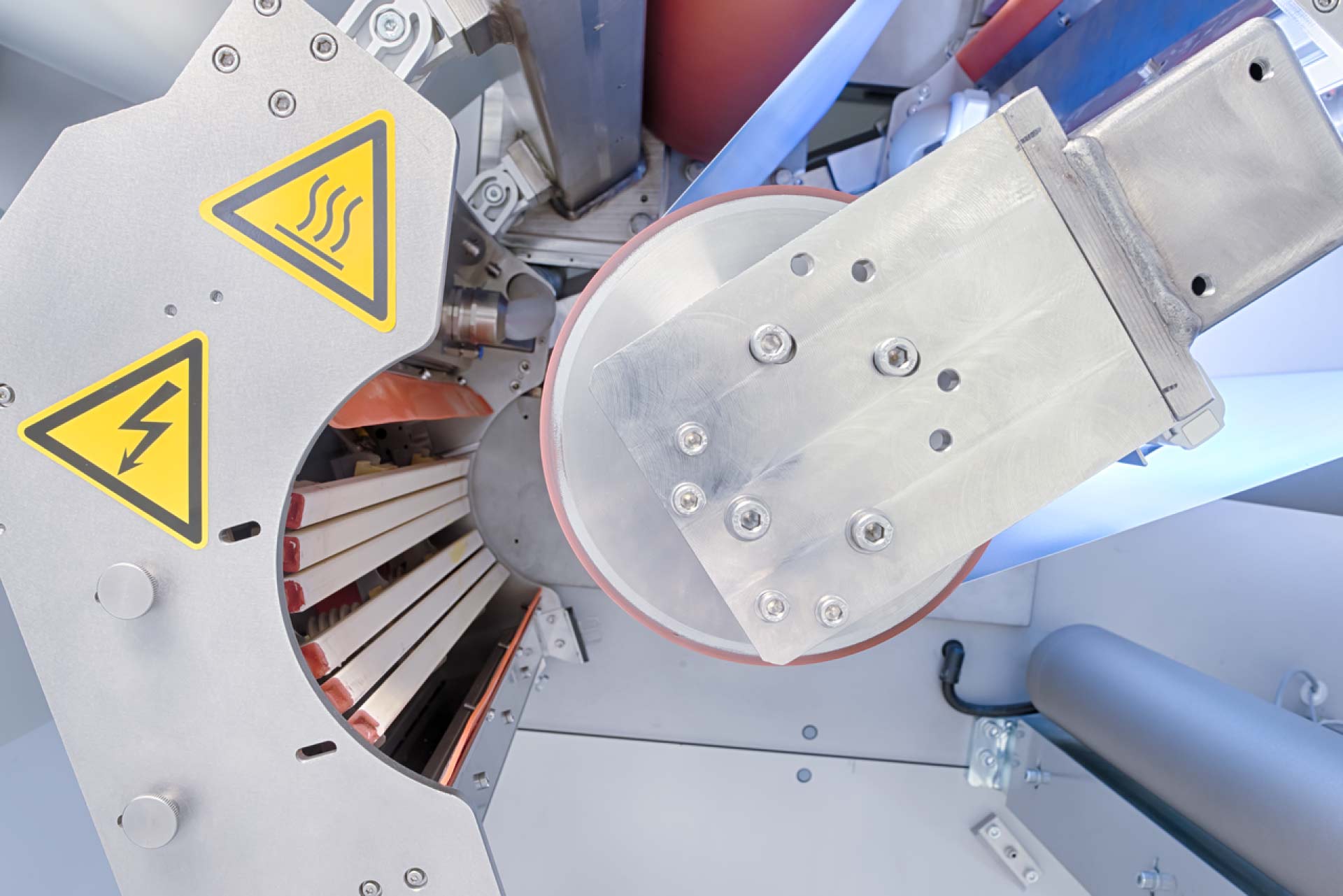

Turning ideas into strong bonds: With the pneumatic press, our Bonding Engineers create prototypes and test samples for laminar bonding - precisely and reliably. We bond a wide range of substrates at temperatures up to 250°C and contact pressures up to 8 bar.

Our infrared heating system conditions substrates — improving the lamination process or activating our thermo-sensitive SBFs (Structural Bonding Films). We can heat materials up to DIN A3 size, preparing them perfectly for the laminator or press.

The FlexoLAB is the dedicated space for the flexo printing industry within our Bonding Arena. To ensure top printing results, we put our plate mounting tapes to the test: using a printing simulator under controlled climatic conditions. At the plate mounter, we also optimize and demonstrate the perfect mounting of adhesive tapes and printing plates onto the sleeve — for maximum precision and performance.

Our Smart Bonding Approach

Our Smart Bonding Approach aims to develop tailored bonding solutions through close collaboration and personalized consulting. From the initial idea, our teams stand by you as competent partners to collaboratively create innovative and sustainable bonding concepts.

Application

Understanding the application conditions is essential to selecting the right adhesive. Lohmann's engineers guide to select the suitable bonding technology.

Product and Production Choice

Tools

Tools and engineering support for manual, semi-automatic, or automatic dispensing, cutting, and more guarantee safe and efficient customers' applications.

Services

Also during the production phase and beyond, providing full supply chain services through to traceability of delivery and processed materials.

From Challenge to Solution: How We Make Know-How Count

From industry-specific demands to cleanroom conversion – this is how we translate bonding knowledge into value you can build on.

At Lohmann, we don't believe in off-the-shelf solutions. We believe in understanding your process, your product, and your goals – and combining our adhesive expertise with your specific requirements. That’s what makes our know-how so valuable: it’s built on real projects, real challenges, and real results.

Our Integrated Value Chain

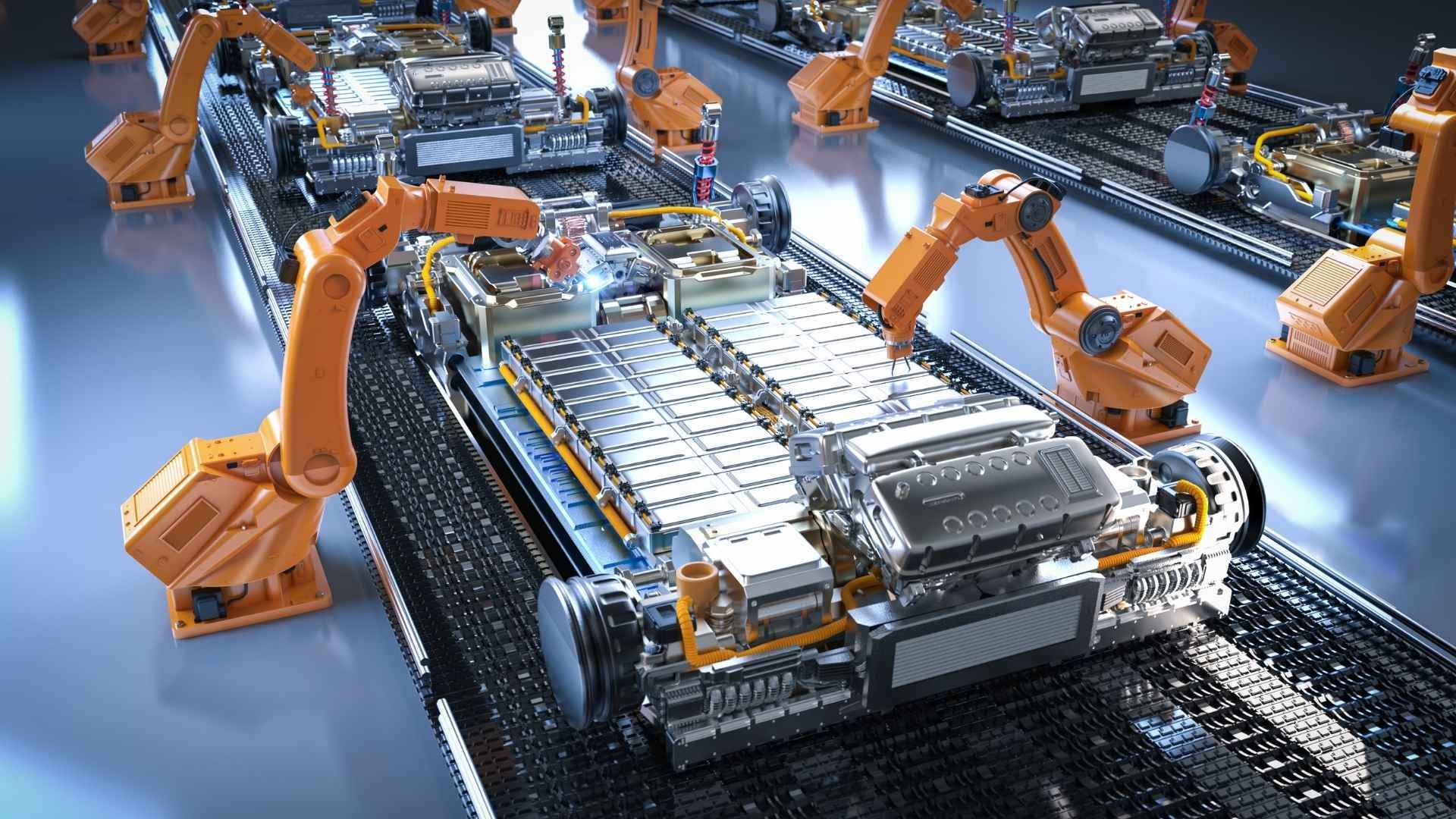

With over 170 years of engineering experience, Lohmann offers deep expertise in designing and executing complex development projects.

Our fully integrated value chain – from in-house adhesive formulation to precision die-cutting and automated assembly – ensures maximum flexibility, short decision-making paths, and reliable quality, all from a single source.

From the first idea to full process integration, we accompany you every step of the way. Whether prototyping or series production, high-tech adhesive tapes or customized die-cuts: Lohmann manufactures your solutions independently of intercontinental supply chains, using a variety of high-precision technologies such as laser plotting, rotary die-cutting, and more – always maintaining ultra-tight μm tolerances.

Lohmann: Your Partner for Smart Bonding Solutions

From the first idea to a real application, our Bonding Arena is where innovation and collaboration come together.

Across industries - from automotive and electronics to medical and industrial applications - we develop bonding solutions that are smart, sustainable, and tailored to your needs. Ready to turn your ideas into reality?

Contact Peter Harendt (Head of Application Technology) to start your journey with us.

Ready for what's next?

Discover how we develop advanced adhesive technologies, align functional performance with sustainability, and deliver reliable solutions for the challenges of tomorrow.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding: news for your industry, about new products and applications and tips for efficient processes and smart designs.