Structural Bonding Technology

Combine the best of two worlds: the benefits of pressure sensitive adhesive tapes and liquid adhesives for crucial benefits: improved cost-efficiency, increased process reliability and higher bonding strength.

Innovative Reactive Films and Tapes Three Advanced Technologies

Reactive films and tapes are dimensional precise and pre-applicable. This guarantees quick and clean processing. Besides both thermally activated tape technologies, polyurethane and epoxy, Lohmann developed a UV- activatable tape technology called UV-LUX® which has semi-structural properties through a cross-linking mechanism.

-

Solvent-free, dry adhesive film

-

Activation within seconds

-

Stays flexible after curing

DuploTEC® SBF Polyurethane

Combined High-tech Technology for Completely New Solutions

Industry’s demands on hightech bonding systems are increasing. Today, numerous safety components or entire assemblies are optimally connected using only adhesives.In order to create connections that are reliable for the various processes, the limits of conventional pressure-sensitive adhesives have to be surpassed and compromises between product development and process optimization need to be amplified.

With their reactive product range Lohmann has provided the answer to these industrial challenges. Within the scope of structural bonding, we have developed innovative products that are much stronger than conventional pressure-sensitive adhesive connections. Also, they combine semi-structural and structural bonding performance with the ease of handling known from adhesive tapes.

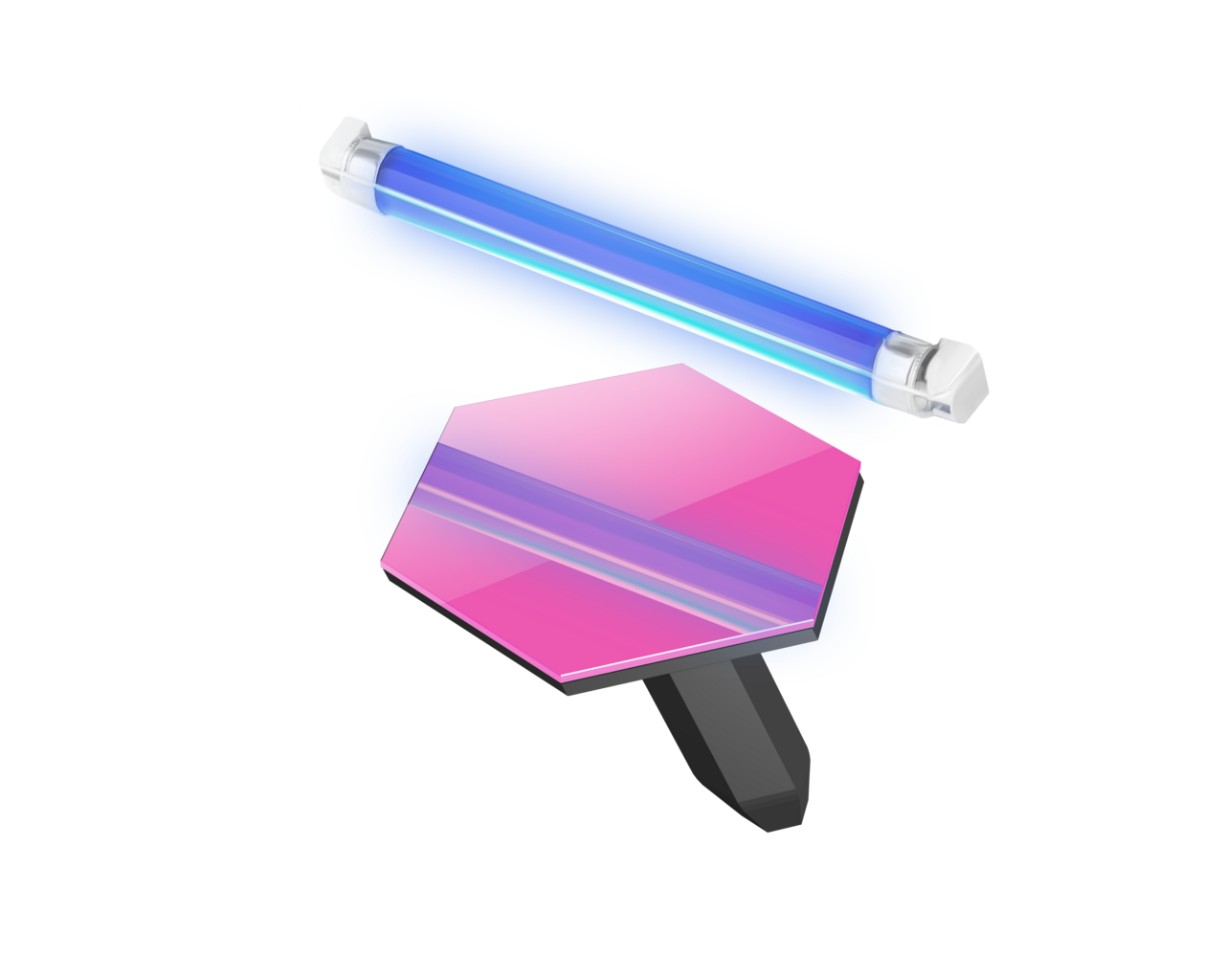

UV-LUX®

UV-Activatable Tape

UV-LUX Technology, the world's first UV-light activatable adhesive tape solution with color change, is an all-rounder. Cold chains and thermal input become obsolete in favor of dark curing. Translucent or thermal resistant materials are no longer needed. Apart from an initial tack, a color change ensures precise, easy and safe manufacturing processes. Patents are pending, first application examples are already there and the potential number of further applications is indefinite.

Technology:

- Modified UV-activatable Epoxy

- Tapes with initial tack

- Formulation and thickness vary depending on application

Process:

- UV-activation with 365nm in seconds

- Color change at activation (optional)

- Up to 10 min. open time

- Immediate handling strength for further processing

- Full strength 24 hours after activation

Lohmann's SBF range combines structural bonding performance with the ease of use offered by adhesive tapes.

It comprises two chemistries: epoxy and polyurethane.

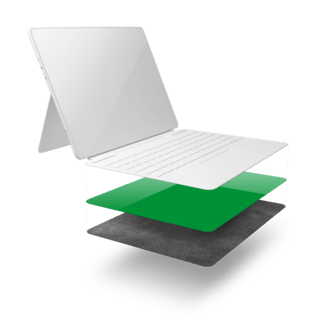

DuploTEC® SBF

Polyurethane High-performance Bonding System

Strong, flexible and quick to process: Thanks to rapid networking at low temperatures, this is the ideal adhesive film for short cycle times.

Technology:

- Thermosetting Polyurethane adhesive system

- Solvent free, dry adhesive film

- Latent reactive with structural bonding characteristics

Process:

- Pre-applicable between 50-55°C

- Storage for up to 3 month after pre-application

- Activation between 70-160°C

- Activation within seconds possible

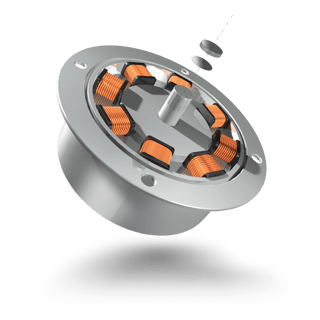

DuploTEC® SBF

Epoxy Adhesive Systems and Tapes

The benefits of pressure-sensitive and structural bonding combined: Easy application through initial tack and structural bonding perfomance after curing. The safe choice for high-strength bonds.

Technology:

- Epoxy based thermosetting tape

- Tape with initial adhesion

- Structural bonding performance

- Various formulations, thicknesses available

Process:

- Curing starts from 130°C (266°F)

- Curing time depending on the temperature and formulation

- Adaptable to individual process conditions

- Pressure: min. 1 N/cm²

Your benefits:

- As easy to apply as an adhesive tape (tack at room temperature)

- Compensation of high static and dynamic forces

- Extremely resistant to ageing and chemicals

- High temperature resistance

Questions, Ideas, or a Need for Consulting?

Then please feel free to contact us! Our expert teams are here to assist you with all your inquiries. Whether technical advice, product information, or individual solutions - we are here for you.

Smart Bonding News for Your Inbox

Register now for our newsletter BONDED and get compact updates on innovative bonding solutions - far beyond classic bonding:

- News for your industry - technological, sustainable, future-oriented

- New products, materials and applications

- Tips for efficient processes and smart designs